Choosing a Strong Clothes Rail Built for Business

When we talk about a truly strong clothes rail, we're not just talking about something that looks sturdy. We're referring to a piece of equipment that has been properly engineered for a demanding professional environment, using specific materials and construction methods to guarantee it can handle the job. It's the difference between a flimsy domestic rail and an industrial-grade workhorse that won’t buckle under the weight of heavy stock.

What Makes a Clothes Rail Genuinely Strong

Think of it like comparing a family hatchback to a commercial transit van. Both have four wheels and an engine, but only the van is built from the ground up for the daily grind of heavy loads and constant use. The same logic applies to clothes rails. A professional-grade rail isn't just a beefed-up version of what you'd find in a bedroom; it's an entirely different beast.

True strength isn’t just a marketing term; it's the result of intentional design. A genuinely robust rail is built on three core pillars that work in harmony to deliver performance you can count on. Getting this wrong is like buying that van based on its paint job instead of its payload capacity—it’s just asking for trouble.

The Three Pillars of Strength

Understanding these three elements is crucial. It’s what separates the dependable workhorses from the decorative pieces that will inevitably let you down when you need them most.

- Industrial-Grade Materials: It all starts with the raw material. Professional rails are built from high-gauge, industrial-grade steel, a world away from the thin, lightweight alloys used in cheaper alternatives. This is what gives the frame its core resistance to bending and warping when loaded up.

- Superior Construction Methods: How the rail is put together is just as vital. Look for welded joints. Welding creates a single, rigid structure that completely eliminates the wobbles and weak points you get with screw-in fittings, which always loosen over time.

- Certified Weight Capacity: This is the ultimate proof in the pudding. A manufacturer's certified weight capacity—often up to 200kg—isn't a vague claim; it's a guarantee that the rail has been properly tested to handle that specific load. It’s a reliable metric that tells you exactly what the rail is capable of.

For anyone curious about the science behind this, it all comes down to the basic principles of structural engineering. This field is dedicated to designing structures that can safely bear loads, and those same concepts apply directly to creating a genuinely strong clothes rail.

This focus on structural integrity is more important than ever in the demanding UK retail scene. As businesses look for every possible efficiency, investing in reliable infrastructure is non-negotiable. For a deeper dive into why these fixtures are so indispensable, have a look at our comprehensive guide on the benefits of heavy-duty rails.

With the UK's clothing retail sector projected to hit £50.0 billion in revenue by 2025, and the women's apparel segment alone accounting for a £37.6 billion market volume, managing high stock levels efficiently is critical. Robust solutions are no longer a luxury—they're a necessity.

What Really Makes a Clothes Rail 'Heavy-Duty'?

To figure out what makes a clothes rail truly strong enough for professional use, you have to look past the superficial details. It’s a bit like how an engineer assesses a bridge – they don’t just look at the road, they examine the steel beams, the joints, and the foundations. It’s exactly the same with a heavy-duty rail. The real strength is hidden in the specifics: the type of steel used, how it's all put together, and the design of the base.

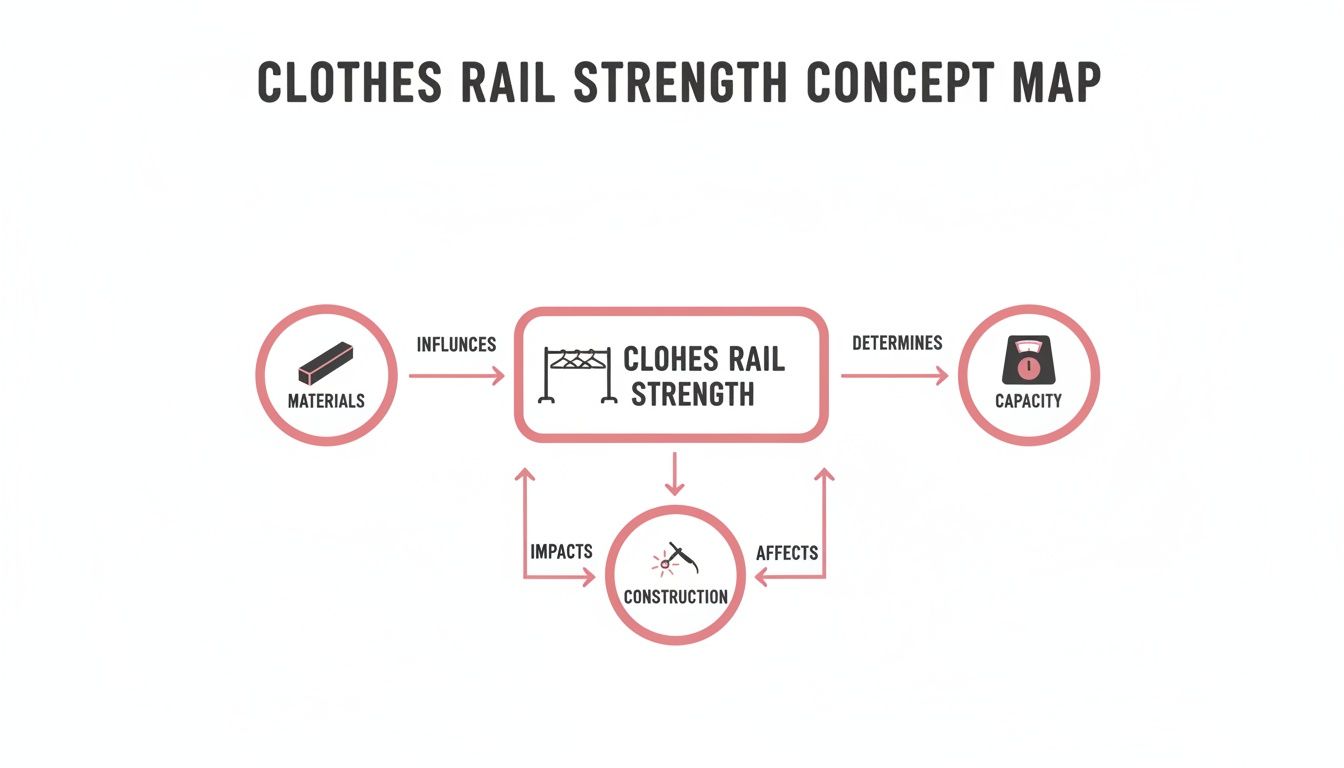

This chart quickly breaks down the core elements that separate a genuinely robust clothes rail from a flimsy domestic one.

As you can see, true strength isn’t just about one feature. It’s an ecosystem where top-notch materials, solid construction, and a realistic weight capacity all work together.

The Steel Frame: The Backbone of Strength

The absolute foundation of any decent rail is its frame, and the material is non-negotiable. Professional-grade rails are always built from industrial-gauge steel, which has a much thicker wall than the flimsy tubing you find on high-street models. Think of it like a hollow chocolate Easter egg versus a solid bar of chocolate – one crumbles under the slightest pressure, while the other is built to last.

This thicker steel is what stops the rail from bending and bowing. When you hang dozens of heavy winter coats or damp garments on a rail, the force on that top bar is immense. A weaker, lower-gauge metal will inevitably start to sag in the middle, which is the first sign of structural failure.

When you're checking the specs, pay close attention to the diameter and gauge of the steel tubing. A larger diameter combined with a thicker gauge (remember, a lower gauge number means thicker steel) is a dead giveaway that the rail is designed for serious commercial work.

And it’s not just about the steel itself. The finish is crucial for longevity, not just looks. A powder-coated or chrome-plated finish adds a tough, protective layer that wards off scratches, chips, and rust, keeping the rail looking professional and structurally sound for years.

Welded Joints: The Unshakeable Connection

How a rail is held together is every bit as important as what it’s made of. For professional environments, the clear winner is welded construction. Welding literally fuses the steel parts together into one solid, seamless unit. This creates an incredibly rigid and stable structure that other assembly methods simply can't compete with.

The cheap alternative you’ll often see involves screw-in fittings or bolts. While this makes the rail easier to flat-pack and ship, it also creates built-in weak points. Over time, the everyday vibrations from being moved around and the constant stress from the load will cause these fittings to loosen. That’s when you get that dreaded wobble—the tell-tale sign of instability.

To really understand the difference, let’s look at a quick comparison.

Material and Construction Strength Comparison

This table breaks down the key differences between a standard rail and a professional one, showing why these details are so critical for strength and reliability.

| Feature | Standard Domestic Rail | Professional Strong Clothes Rail | Why It Matters for Strength |

|---|---|---|---|

| Frame Material | Thin-walled, low-gauge metal or plastic | Thick-walled, industrial-gauge steel | Provides superior resistance to bending, bowing, and denting under heavy loads. |

| Joint Construction | Screw-in fittings or push-button clips | Fully welded joints | Creates a single, rigid unit that eliminates weak points and the dreaded "wobble". |

| Finish | Basic paint or thin chrome plating | Durable powder-coating or thick chrome | Protects against rust, scratches, and chipping, preserving structural integrity. |

| Base Design | Narrow, lightweight base | Wide, H-frame or Z-frame base | Lowers the centre of gravity and provides a stable footprint to prevent tipping. |

| Castors (Wheels) | Small, plastic wheels | Industrial-grade rubber or polyurethane | Ensures smooth movement even under heavy loads (up to 200kg) and won't damage floors. |

As you can see, every component in a professional rail is specifically chosen to contribute to a stronger, more cohesive whole.

A fully welded frame distributes all the weight and energy evenly, preventing any single point from taking too much strain. If you want to dive deeper into how joints are supported, our guide on choosing the right clothing rail bracket has more detail on the hardware involved.

The Base and Castors: The Foundation of Stability

Finally, a strong clothes rail needs an equally strong foundation to stand on. The base design is absolutely crucial for preventing tipping, especially when the rail is packed full or being moved. A wider base creates a lower centre of gravity, just like a weightlifter spreading their feet for maximum stability before a big lift. This wider footprint keeps the rail upright and secure, even if the load isn't perfectly balanced.

Attached to this base are the castors, or wheels. They’re often an afterthought for buyers, but they’re vital for mobility and safety in a professional setting.

- Material Matters: The best rails use industrial-grade rubber or polyurethane castors with steel ball bearings. These materials are built to last, roll smoothly under loads of up to 200kg, and are non-marking, so they won't scuff up your floors.

- Size and Swivel: Bigger castors can handle uneven floors and bumps much more easily, while a full 360-degree swivel makes manoeuvring in a cramped stockroom or on a busy shop floor effortless.

- Braking System: At a minimum, two of the castors must have reliable brakes. This is a non-negotiable safety feature to stop the rail from rolling away on a slight incline or while you’re loading it up.

Cheap plastic castors are one of the most common points of failure on budget rails. They crack under pressure, get jammed with hair and thread, and seize up when the rail is at full capacity. This turns the simple job of moving stock into a frustrating and potentially dangerous struggle. By taking a closer look at each of these components, you can confidently tell a genuinely engineered heavy-duty clothes rail from a weaker imitation.

Choosing the Right Rail for Your Business

Picking the right strong clothes rail isn't as simple as just checking the maximum weight it can hold. It's really about matching the rail's design and features to what you do every single day. The perfect rail for a chic high-street boutique would be a terrible fit for a hectic stockroom, and what a pop-up shop needs is something else entirely.

The best place to start is by thinking about your daily operations. When you picture how you'll actually use the rail, you can move past the technical specs on a page and start seeing the ideal solution—one that solves your unique problems, whether that’s boosting your brand's image, cramming in more stock, or making setup and breakdown a breeze.

Let's walk through a few common scenarios and pinpoint what really matters for each.

The High-Street Fashion Boutique

On the shop floor, a clothes rail is so much more than a storage rack; it's a vital piece of your visual merchandising. Here, strength and style have to go hand-in-hand to create that premium, inviting atmosphere. The rail itself becomes part of the furniture, quietly reflecting your brand’s identity.

You’ll want to focus on features that deliver stability without sacrificing an ounce of style:

- Premium Finishes: Think about how a sophisticated matte black or a trendy brushed bronze finish could elevate your displays, making the rail a core part of the shop's aesthetic.

- Minimalist Design: Clean, industrial pipe-style rails or minimalist frames keep the attention where it belongs: on your clothes.

- Concealed Strength: The rail absolutely must hold valuable garments without sagging, but you don't want to see chunky, agricultural-looking welds. Look for subtle engineering, like clean joints and a solid, well-balanced base.

The Back-of-House Stockroom

Step into the stockroom, and the game changes completely. Aesthetics go out the window, replaced by a ruthless focus on function and efficiency. The only goal here is to store as much stock as possible, safely and accessibly. This is where a truly heavy-duty rail earns its keep.

You need a rail that's built like a tank. Look for specs that shout "unbreakable":

- Exceptional Weight Capacity: A certified capacity of 200kg or more isn't a luxury; it's essential for holding hundreds of items, from heavy winter coats to stacks of denim, without buckling.

- Industrial-Grade Castors: Don't even consider anything less than large, robust rubber wheels for gliding across concrete floors. At least two of them must have solid, reliable brakes for safety.

- Maximum Durability: Forget fancy finishes. You need a simple, tough powder-coated steel frame that can take the inevitable knocks and scrapes of a busy warehouse.

The UK's clothing market is set to recover to £67.8 billion by 2025, with retailers needing robust fixtures to manage inventory. A strong clothes rail, rated to UK standards for loads over 200kg, is essential for stability in a sector where e-commerce now accounts for 73% of fashion sales. These rails help physical stores create impactful displays to counter online dominance. For more insights on market trends, explore the full state of UK fashion ecommerce in 2025.

The Pop-Up Shop or Market Stall

For anyone in the world of temporary retail, it's all about being nimble. If you're running a pop-up, event stand, or market stall, you need a strong clothes rail that's easy to move, a cinch to assemble, and tough enough to withstand a long day's trade.

Your checklist for a portable rail should include these non-negotiables:

- Ease of Assembly: Find models designed for a quick, tool-free setup. Systems with push-pins or simple locking mechanisms are a lifesaver when you're against the clock.

- Lightweight yet Strong: The frame needs to be light enough for one person to carry, but it still has to be engineered from quality steel so it doesn't wobble once it's built and loaded.

- Compact Storage: The ability to collapse the rail down into a compact size that fits in the back of a car or van is absolutely critical.

By thinking through these different scenarios, you can quickly zero in on the features that will make a real difference to your business. Making the right choice is an investment in a tool that won't just do its job for years to come, but will actively help you achieve your goals. For more advice tailored to your needs, check out our in-depth guide to choosing strong clothes rails.

Assembly and Maintenance for Lasting Performance

A professional-grade strong clothes rail isn't just a purchase; it's an investment in your business's day-to-day operations and presentation. Like any vital piece of kit, its lifespan and reliability depend on more than just good design. Getting the assembly right from day one and keeping up with a little basic care are what truly make it last.

Think of it like a new van for your business. You wouldn't just drive it off the forecourt and ignore the service schedule. Getting it set up correctly and checking it over now and then ensures it stays safe, stable, and ready to work hard for years.

Your Initial Assembly Guide

The single most important thing you can do to guarantee your rail’s stability is to assemble it properly from the very beginning. A rushed or sloppy setup can undermine the strongest frame, introducing wobbles and weaknesses that only get worse over time.

While many of our rails are designed for a straightforward build, some of the more complex systems can be tricky. If you're short on time or just want absolute peace of mind, you can always look into professional furniture assembly services. But for most models, a few key steps are all it takes to get a rock-solid result.

Here's how to ensure a secure and perfectly level setup:

- Find a Level Surface: Before you even open the box, find a flat, even bit of floor. Assembling on a slope can fool your eye, leaving you with a permanently skewed frame that will never be truly stable.

- Hand-Tighten Everything First: As you connect the parts, only tighten the bolts and screws by hand. This gives you just enough wiggle room to get every component perfectly aligned before you lock it all down.

- Get it Square: This is the crucial step. Use a spirit level on the top rail and the vertical posts. A perfectly square and level frame distributes weight exactly as it's meant to, putting no undue stress on any single joint.

- Tighten Up Systematically: Once you’re happy it’s perfectly level, go around and tighten all the fittings properly with the correct tools. Make sure every connection is firm and secure, but don't go overboard and strip the threads.

Long-Term Preventative Maintenance

With your rail built and in use, a little ongoing attention is all it needs. Regular checks can spot small problems before they become big ones, protecting your investment, your stock, and your team. The easiest way to stay on top of it is to build these simple tasks into your regular cleaning routine.

Just follow this simple maintenance checklist:

- Weekly Castor Clean: In any busy shop or stockroom, castors are magnets for hair, thread, and dust. Once a week, tip the rail on its side and clear out any gunk from the wheels. This keeps them rolling smoothly and prevents jamming.

- Monthly Joint Inspection: Give the whole rail a gentle shake once a month to feel for any looseness. Have a quick look at all the joints and tighten up any fittings that might have worked themselves loose with daily use.

- Regular Frame Wipe-Down: Use a soft, damp cloth to keep the frame free of dust and fingerprints. For chrome or powder-coated finishes, steer clear of harsh chemicals—a bit of mild soapy water is all you need for stubborn marks.

A well-maintained rail is a safe rail. These quick checks aren't just about making your equipment last longer; they're a vital part of keeping your workplace safe and preventing a sudden collapse that could damage stock or cause an injury.

By taking a few minutes for proper assembly and routine care, you ensure your strong clothes rail delivers the performance it was built for. This simple, proactive approach protects its structural integrity, keeps it looking professional, and guarantees it will remain a reliable workhorse for your business. For a closer look at specific fittings, our guide on clothes rails and brackets offers more detailed advice.

Essential Accessories and Enhancements

A truly strong clothes rail is more than just a piece of metal—it's the backbone of a flexible, modular display system. With the right accessories, you can turn a simple rail into a bespoke solution that solves specific retail challenges, makes the most of your space, and ultimately, improves your customer's experience.

Think of the basic rail as a robust chassis. These enhancements are the custom modifications that get it ready for any job you throw at it. They allow a single piece of hardware to adapt to changing stock, seasonal displays, and different environments, proving that a rail’s value lies not just in its strength but in its versatility.

Customising Your Rail for Maximum Impact

By picking the right add-ons, you can tackle common merchandising and stock management headaches with simple, effective tools. These accessories are designed to integrate seamlessly with a heavy-duty frame, pushing its functionality far beyond just hanging clothes.

Here are a few key accessories worth considering:

- Height Extension Poles: If you’re selling long garments like maxi dresses, full-length coats, or bridal wear, these are non-negotiable. They give you the clearance needed to present merchandise perfectly, without it dragging on the floor.

- Centre Bars: This is the easiest way to instantly double your hanging capacity. By adding a second, lower tier, you can effectively turn one rail into two—ideal for children's wear, folded trousers, or shirts.

- Specialised Castors: Not all floors are created equal. While standard heavy-duty castors are fantastic, you might need non-marking rubber wheels to protect a delicate studio or boutique floor from scuffs.

These customisations aren't just a "nice-to-have"; they’re essential in a competitive retail world. The UK apparel market is expected to hit £68.7 billion by 2025, and physical stores need to be incredibly efficient and visually appealing to stand out. It's no wonder retailers are favouring modular rails with adjustable heights to handle the sheer variety of garments purchased by UK consumers, who buy an average of 61.2 pieces each year. You can discover more insights about the UK fashion industry's future on springfair.com to stay ahead of the curve.

Enhancing Organisation and Customer Experience

Beyond the structural bits, other accessories are all about improving your day-to-day workflow and making shopping easier for your customers. These small touches can have a surprisingly big impact on efficiency and sales.

Rail dividers, for instance, are a brilliantly simple tool. They let you clearly segment garments by size, colour, or collection, creating an organised display that’s easy for shoppers to browse. It stops the frantic rummaging and helps keep your shop floor looking tidy and professional.

Another game-changer is the ticket holder. These clip-on additions provide a clear, consistent way to show pricing, promotions, or size details right on the rail. No more customers hunting for tags—it streamlines the whole shopping process.

By combining these elements, a strong clothes rail becomes a central part of your merchandising strategy. You can also explore options to safeguard your stock; our guide on garment racks with covers has more ideas for protecting valuable inventory. In the end, these enhancements are what turn a purely functional item into a real strategic asset.

Common Questions About Strong Clothes Rails

Even after getting to grips with the technical side of materials and construction, a few practical questions always pop up when you're about to invest. Getting these details straight is the final step in making sure you choose a rail that fits your business perfectly and works like a charm from day one.

Let’s run through some of the most common queries we hear from business owners. These usually get into the nitty-gritty of using heavy-duty kit in a commercial space, from making sense of the specs to what they're like to live with day-to-day.

How Is the Weight Capacity of a Clothes Rail Measured?

When you see a weight capacity like 150kg or 200kg, that number comes from a specific test. Manufacturers apply what’s called a Uniformly Distributed Load (UDL) across the full length of the top bar. Think of it as simulating the weight of clothing spread out evenly, which is how you'll be using it.

The key thing to remember is that this isn't a 'point load' capacity. You can't just hang all 200kg on one small section of the rail. For the best performance and to make sure your rail lasts, always spread the load as evenly as you can. And always check that the capacity is a certified figure from the manufacturer, not just a rough guess.

Can I Use a Commercial Heavy Duty Rail at Home?

Absolutely. While they're built to withstand the tough life of a commercial environment, a strong clothes rail is a fantastic investment for home use. They're perfect if you have an extensive wardrobe or a hefty collection of winter coats. They also make a brilliant, robust storage solution for a loft, garage, or utility room.

On top of that, the industrial look—especially the popular matte black or pipe-style finishes—is a great fit for a lot of modern interior designs. You get professional-level durability that will easily outlast any flimsy domestic alternative.

What Is the Most Common Mistake When Buying a Clothes Rail?

By far, the biggest mistake we see is people choosing a rail based on looks or a cheap price tag while completely overlooking the build quality. There are plenty of stylish rails out there that use thin metal tubing and weak plastic or screw-in fittings that are simply guaranteed to buckle under any serious weight.

Always put the technical specs first. Check the type of steel used, look for welded joints that provide proper rigidity, and pay attention to the quality of the castors. A slightly higher initial investment in a well-engineered rail will save you a world of frustration and money down the line.

Are All Castors on Strong Clothes Rails the Same?

Not at all. The castors are a critical part of the rail's overall performance, and they vary hugely in quality. Top-tier rails will always use industrial-grade castors, typically made from rubber or polyurethane with strong steel bearings. These are designed to glide smoothly even under a full load, and they won’t scuff or mark your floors.

In contrast, cheaper rails often come with hard plastic wheels that can easily crack, jam up, or refuse to budge once you've loaded the rail up. If you need to move your stock around, investing in a model with superior castors isn't just a nice-to-have—it's essential for usability and safety.

At Display Guru, we specialise in providing professional-grade display solutions built to last. Explore our complete range of strong, reliable garment rails designed for the demands of UK businesses by visiting us at https://www.displayguru.co.uk.