Choosing Strong Clothes Rails for Retail and Home

Choosing the right clothes rail isn't just about tidying up; it's a serious investment in how you organise and care for your garments. It’s easy to underestimate just how heavy a collection of clothes can be, which often leads to bowed rails, tangled hangers, and even damaged items. A truly strong clothes rail isn't a temporary fix—it's a permanent, reliable solution that protects your clothing and brings order to your space.

Why Your Choice of Clothes Rail Matters

A clothes rail might seem like a simple piece of kit, but its impact on your home or business can be massive. For anyone at home, it's the difference between a chaotic wardrobe and a calm, well-organised space. But for boutique owners, tailors, and designers, it's a fundamental business tool that safeguards valuable inventory and keeps daily operations running smoothly.

A flimsy rail that buckles under pressure is more than just an annoyance. It can lead to real financial loss from damaged stock and creates an unprofessional, messy environment that nobody wants.

Investing in a proper heavy-duty clothes rail means you're committing to preserving the quality of your garments. Whether we're talking about your personal collection of winter coats or a designer's new line, a well-chosen rail prevents the unnecessary creasing and stretching that happens when clothes are crammed onto a structure that just can't cope.

More Than Just Storage

Think of a robust clothes rail as an active player in garment care and presentation. It gives each item enough breathing room, ensuring proper air circulation that is vital for preventing mustiness and keeping fabrics in top condition. In a shop or studio, this function is even more critical, helping you create compelling visual displays that draw customers in.

After all, great organisation and presentation are cornerstones of retail success. If you want to explore this further, our guide on visual merchandising guidelines offers some brilliant insights for creating displays that are both attractive and practical. A strong rail really is the backbone of any great retail setup.

By selecting a rail designed for durability, you are not just organising clothes; you are protecting an investment. The right choice prevents the slow, costly damage caused by overloading and ensures your garments remain in pristine condition, ready for wear or sale.

The True Cost of a Weak Rail

It's tempting to go for a cheaper, less durable rail, but it almost always proves to be a false economy. The constant cycle of replacing broken rails, not to mention the potential damage to your clothing or merchandise, quickly eats up any initial savings. It’s better to think of a strong clothes rail as essential infrastructure for your wardrobe or your business.

- For Homeowners: It's a lasting solution for bulky items like winter coats, suits, and formal wear, putting an end to the frustration of collapsed rails.

- For Professionals: It can handle the weight of entire collections, heavy fabric bolts, or large client orders without any risk, ensuring your workflow is never disrupted by equipment failure.

Ultimately, choosing a strong rail is about having a bit of foresight and placing real value on your possessions.

What Really Makes a Clothes Rail Strong?

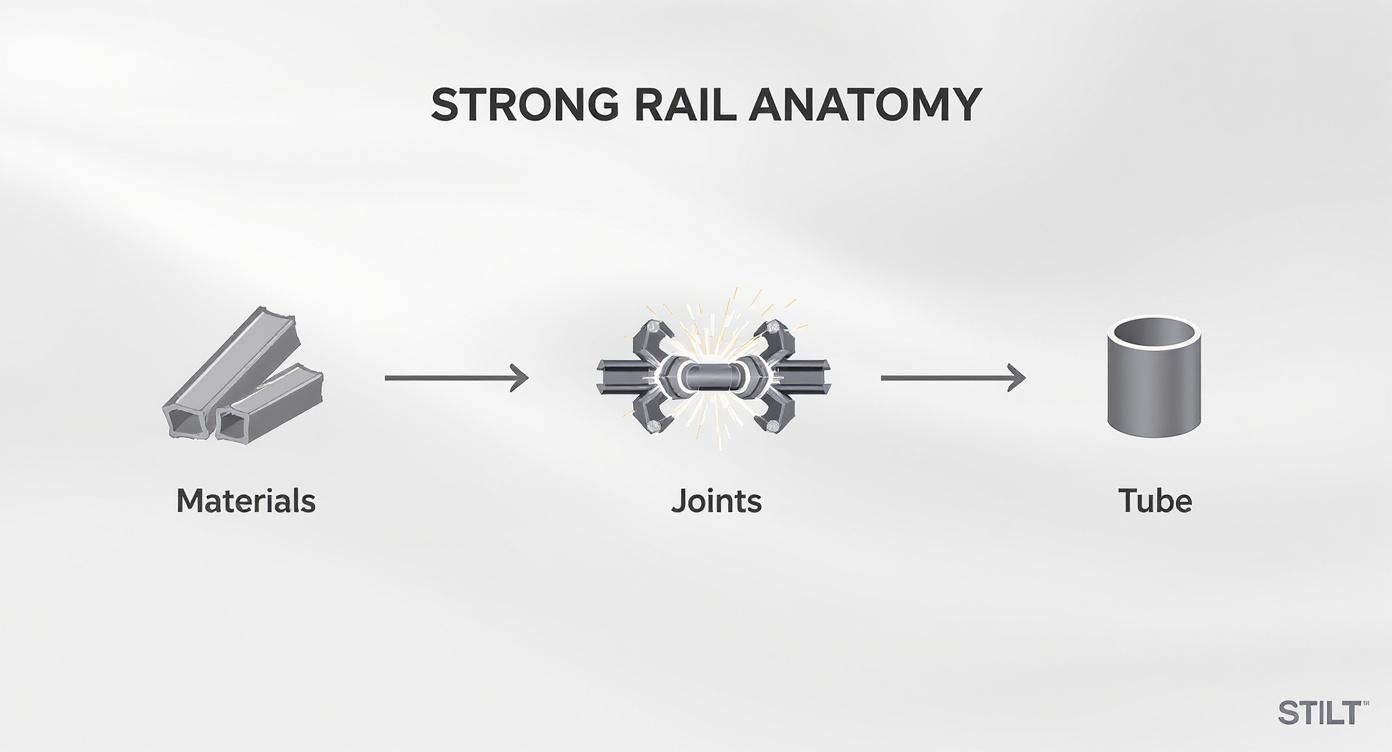

Ever wondered what gives a clothes rail its backbone? It’s not just one single thing. True strength comes from a smart combination of top-notch materials and clever construction, all working together. Think of it like a miniature suspension bridge – its power to hold a heavy load comes down to the quality of every single component, from the steel it’s made of to how the joints are fastened.

Getting to grips with these core elements is the key to telling a genuinely tough rail from a flimsy one that'll buckle under pressure. This insight lets you see past the sales pitch and judge the real-world durability of any rail you're looking at for your shop, studio, or even your home.

It All Starts With the Metal

The material is the absolute foundation of a clothes rail's strength. While you'll find a few different metals on the market, when it comes to serious heavy-duty work, industrial-grade steel is the undisputed king. Its natural strength and stiffness make it the perfect candidate for holding a lot of weight without bending or twisting over the years.

But here's a crucial point: not all steel is the same. The thickness of the metal, known as its gauge, is a dead giveaway of its durability. With steel gauge, the numbers work in reverse – a lower number means a thicker, stronger metal. So, a 16-gauge steel tube is much, much tougher than a 22-gauge one, making it a far better choice for hanging heavy stock like winter coats or a whole collection of jeans.

A common slip-up is getting distracted by a rail's shiny finish. The real strength is hidden in the metal's thickness and quality. A thicker gauge isn't just a feature; it's a direct investment in the rail's future stability and how much it can actually hold.

To help you choose, here's a quick rundown of the most common materials.

Comparing Materials for Strong Clothes Rails

A quick comparison of common materials used in clothes rails, highlighting their suitability for different applications.

| Material | Typical Load Capacity | Corrosion Resistance | Best For | Considerations |

|---|---|---|---|---|

| Industrial-Grade Steel | 100kg - 150kg+ | Moderate (often coated) | Retail stockrooms, workshops, heavy garment display | The strongest option, but can be heavy and susceptible to rust if the coating is damaged. |

| Stainless Steel | 70kg - 100kg | Excellent | Boutiques, humid environments, long-term displays | Aesthetically pleasing and rust-proof, but typically more expensive than standard steel. |

| Aluminium | 30kg - 50kg | Excellent | Pop-up shops, market stalls, lightweight home use | Very lightweight and rust-proof, but not suitable for heavy, continuous loads. |

| Coated Steel (e.g., Chrome) | 60kg - 90kg | Good | General retail, domestic wardrobes, showrooms | Offers a good balance of strength and appearance, but watch for chipping that can lead to rust. |

Ultimately, for pure, unadulterated strength, you can't beat industrial-grade steel. It’s the workhorse of the retail and tailoring world for a reason.

Joints and Construction: Welded vs. Screwed

How a rail is put together is just as vital as what it's made from. You’ll generally find two main construction methods: welding and screw-in assembly, and they offer very different levels of stability.

-

Welded Joints: This is the gold standard for strong clothes rails. Welding literally melts the metal parts into one another, creating a single, solid structure. This gets rid of any potential weak spots, leaving you with an incredibly rigid frame that can handle huge, constant pressure without ever getting loose.

-

Screwed Fittings: Rails that you assemble with screws and bolts are certainly convenient. They can be flat-packed for easy transport and put together or taken down without much fuss. While a well-made screwed rail is fine for many situations, those joints can become weak points over time and might need tightening now and then to stop them from wobbling under a heavy load.

For the toughest jobs in a busy shop or a tailor's workshop, a fully welded frame is simply unbeatable for its raw structural integrity.

Tubing Diameter and Shape

The diameter of the rail's tubing also makes a big difference to its overall strength. It’s simple physics: a wider tube has more material to resist bending and spreads the weight of the clothes more evenly along its length. A rail with a chunky, substantial tube is just better equipped to handle the downward force of all that fabric.

Even the shape of the tube can matter. Round tubes are the most common, but you'll see some heavy-duty rails using oval-shaped top bars. This isn't just for looks; this design provides much greater resistance to sagging along the horizontal line, which is exactly where all the weight is focused. It's a small but effective bit of engineering that really boosts the rail's ability to hold heavy collections without bowing in the middle.

When you’re sizing up a rail, don't just look at its height and length—look at the physical substance of its parts. Strong, secure brackets are also a must; you can find out more about picking the perfect clothing rail bracket in our detailed guide. Understanding how all these pieces fit together gives you a much clearer picture of the rail's sturdiness and whether it's the right tool for your job.

Calculating Your Load Capacity and Sizing Needs

Choosing a strong clothes rail without first knowing what you need it to hold is like buying a van without checking its payload. You might end up with something that looks the part, but it’s guaranteed to buckle under the first sign of real work. To sidestep the all-too-common problem of an overloaded, failing rail, you need a clear picture of your storage and space requirements from the outset.

This isn’t about pulling out a calculator; it’s about practical estimation. The best place to start is by grouping your garments by type. A collection of 15 heavy wool coats can easily weigh over 30kg, whereas the same number of silk blouses might barely tip the scales at 5kg. This simple exercise gives you a realistic idea of your total weight, stopping you from underestimating the load and buying a rail that just isn’t up to the job.

Distributed Load vs Point Load

It’s not just how much weight you hang, but how you hang it. Understanding this is key to your rail’s long-term health. Think about carrying a long plank of wood: it’s much easier to hold it flat against your body (a distributed load) than it is to balance it on a single fingertip (a point load). The exact same principle applies to your clothes rail.

- Distributed Load: This is what you should always aim for. Garments are spaced evenly along the entire rail, sharing the stress across the whole structure. This maximises its capacity and keeps it stable.

- Point Load: This is when weight is piled into one small area—for instance, slinging several heavy bags over one spot. This creates a serious stress point that can cause even the toughest rails to bend or fail over time.

For maximum durability, always try to spread the weight out as evenly as you can. It's a simple habit that drastically reduces the strain on the rail’s materials and joints, giving it a much longer life.

This diagram breaks down how a rail is constructed to handle these forces, showing how the raw materials, complex joints, and final tubing all work together.

As you can see, a rail's strength is a complete system. The quality of every single part—from the raw steel to the welded joints—directly contributes to its ability to bear a heavy load.

Measuring Your Space Accurately

Once you've got a handle on the weight, it's time to measure your physical space. A rail that’s too big will make a room feel cramped and awkward, while one that’s too small is just a waste of valuable floor space. Measure the height, width, and depth where you plan to put it, but don't forget to account for the clothes themselves.

You need enough height so that long items like dresses and coats don’t end up dragging on the floor. At the same time, make sure there’s enough depth from the wall to stop clothes from getting squashed. This also promotes good air circulation, which is essential for keeping fabrics fresh. For a deeper dive, our article on clothes hanging poles offers extra tips on getting the most out of your hanging space.

In a retail setting, this isn't just about storage—it's about operational efficiency. The right size rail has a direct impact on your inventory density, visual merchandising, and the customer's experience. It ensures your products look great and are easy for shoppers to browse.

Getting this right is more important than ever. With the UK clothing retail market projected to hit £50 billion in 2025, the demand for reliable, professional-grade storage in shops and homes is only going to increase.

The principle of getting the dimensions right applies to all sorts of display equipment, not just rails. As this guide on choosing the perfect roller banner size points out, whether it's for garments or graphics, correct sizing is fundamental to effective presentation. By carefully working out your needs beforehand, you can find a strong clothes rail that not only holds everything securely but also fits your environment perfectly.

Mastering Installation for Maximum Durability

https://www.youtube.com/embed/-NaS-m7oVIc

A powerful engine is useless without a solid chassis, and the same thinking applies to your garment rails. You can buy the strongest, most industrial-grade steel rail on the market, but it will let you down if it’s not installed correctly. Getting the assembly and mounting right isn't just a suggestion—it's absolutely essential for the stability, safety, and longevity of your investment.

An improperly fitted rail is more than a simple nuisance; it's a real hazard. In fact, poor installation is one of the biggest reasons for equipment failure, which can lead to damaged stock, broken fixtures, and even personal injury. By taking the time to master a few key techniques, you can be confident your rails will perform exactly as they were designed to.

Wall-Mounted Rails: Securing Your Foundation

When you’re fitting wall-mounted rails, the single most important rule is to anchor them into something solid. Plasterboard on its own just doesn't have the strength to support a serious amount of weight. Your main task is to find the wooden wall studs running behind the plasterboard.

These vertical beams are the skeleton of the wall, providing all its structural support. The easiest way to find them is with an electronic stud finder. Once you've marked their positions, you can drill directly into the wood for an unshakeable fixing that will handle a substantial load without any trouble.

But what if the studs aren't where you need the rail to be?

- For Plasterboard: You'll want to use heavy-duty toggle bolts. These are clever fixings with spring-loaded 'wings' that pop open behind the board, spreading the load across a much wider area. This stops the screw from just tearing a hole in the plaster.

- For Brick or Masonry: For solid walls, you’ll need masonry plugs and screws. As you drive the screw in, the plastic plug expands, creating a powerful friction grip inside the brick or blockwork.

Choosing the right hardware is half the battle. For a deeper dive, you can explore our advice on selecting the right clothes rail and brackets to make sure every part works together flawlessly.

Freestanding Rails: Building a Stable Base

With freestanding models, stability all comes down to careful and precise assembly. A wobbly rail is almost always the result of fittings that haven't been properly tightened. As you put it together, make sure every single screw and bolt is tightened fully to create a rigid, solid structure.

Don't rush it. Follow the instructions step by step, and listen for the click or feel the resistance that tells you a component is securely in place. Many heavy-duty rails even use press-stud mechanisms that give you that satisfying "click" to confirm a solid connection.

The secret to a wobble-free freestanding rail is methodical assembly. It’s also a good idea to periodically check and retighten all the fittings, especially after the first few weeks of use, as things can settle a bit under the initial load.

High-quality, lockable castors are another game-changer for freestanding units. They obviously make the rail easy to move for cleaning or rearranging your shop floor, but they're crucial for safety too. Always engage the brakes once the rail is where you want it. This prevents it from rolling away unexpectedly, which is especially important on slightly uneven floors.

Proactive Maintenance for Long-Term Durability

Once your strong clothes rail is installed, it’s not something you should just set and forget. A simple, proactive maintenance routine will protect your investment and keep it in top condition for years to come.

Your Monthly Maintenance Checklist:

- Tighten All Fittings: Give all the screws, bolts, and connections a quick check. The small vibrations from everyday use can sometimes cause them to loosen over time.

- Inspect for Stress: Take a close look at the joints, welds, and the centre of the top bar. You're looking for any early signs of bending or metal fatigue. Catching these things early prevents a major failure down the line.

- Clean the Surface: Wipe the rail down with a soft, dry cloth to get rid of dust. This simple step keeps your garments from getting marked and maintains the rail's professional look.

- Check Castors: For any mobile units, make sure the wheels are clear of hair and debris and that the locking mechanisms are working as they should.

This straightforward approach will ensure your rail remains a safe, reliable, and effective tool for your business.

When you’re a professional in retail or fashion, a clothes rail isn't just a bit of furniture—it’s a core piece of your equipment. In these high-stakes environments, a standard domestic rail just won’t cut it. Professionals need strong clothes rails that are built to take a real beating, day in and day out.

From the chaos of a retail stockroom to the focused calm of a design studio, these heavy-duty workhorses are chosen for one simple reason: they don't fail. They're not just hanging clothes; they're protecting valuable stock, keeping workflows moving, and making a space look its best. The right rail is your silent, most reliable business partner.

The Retailer’s Mobile Stockroom

In any shop, flexibility is the name of the game. Boutiques and big-name stores use heavy-duty mobile rails to create dynamic displays that can be shifted around in moments. Think about a big seasonal changeover or the start of a sale. Instead of carting armfuls of clothes back and forth, staff can roll out entire collections right onto the shop floor.

This ability to move stock easily is a godsend during busy periods. You can adapt the store layout on the fly to manage crowds or shine a spotlight on a new promotion. And because these rails are built tough, you can load them up with heavy winter coats or stacks of denim without a second thought, maximising your floor space without risking a collapse.

The Designer and Tailor’s Studio Hub

For a fashion designer, tailor, or costume maker, a solid rail is absolutely essential. These creative spaces are filled with all sorts of materials, from delicate silks to heavy bolts of wool. A strong clothes rail gives you the confidence to organise multiple client projects and hang heavy fabrics without worrying about the structure giving way.

A collapsed rail in a studio is more than an inconvenience; it’s a disaster. It can ruin bespoke garments, throw deadlines into chaos, and turn a professional space into a mess. Investing in a heavy-duty rail is simply good insurance.

This is especially true for theatre productions, where organisation is everything. Our guide on https://www.displayguru.co.uk/blogs/news/costume-rails dives into how production teams manage enormous wardrobes, making sure every single piece is accounted for and ready for the stage. For these pros, reliability isn't a feature—it's a requirement.

The Backbone of E-commerce Fulfilment

The boom in online shopping has turned the humble stockroom into a high-speed fulfilment hub. In this world, efficiency is king, and that means having equipment that is both durable and mobile. Heavy-duty rails are used to shift large batches of clothing from storage shelves to packing stations, a process that would be painfully slow with flimsy rails.

And this isn't slowing down. With online fashion sales in the UK projected to grow by 4.6% in 2025 to hit around £21.01 billion, the pressure on warehouse operations will only increase. Strong, reliable rails are the unseen workhorses supporting this massive industry.

Photography Studios and Showrooms

In a showroom or a photography studio, it’s all about presentation. Garments have to look perfect and wrinkle-free, whether for a buyer or a camera. Heavy-duty rails allow stylists to prep and organise outfits for a shoot, keeping the whole process running smoothly. When you're optimizing a product photography studio setup, you quickly realise that having robust garment storage is fundamental to the workflow. A sturdy rail ensures every piece is protected and presented professionally, reflecting the quality of the brand itself.

The right tool for the right job is a principle that holds true across these professions. Here’s a quick breakdown of which rails work best in different settings.

Professional Use-Case Rail Recommendations

| Professional Setting | Recommended Rail Type | Key Features | Primary Benefit |

|---|---|---|---|

| Retail Boutique | Heavy-Duty Mobile Rail | Lockable castors, sleek finish (e.g., chrome) | Versatile merchandising and easy floor resets |

| Tailoring Studio | Reinforced Static Rail | High load capacity (100kg+), fixed feet | Stability for heavy fabrics and valuable garments |

| E-commerce Warehouse | Industrial Mobile Rail with Tiers | Multi-level hanging, durable steel frame | Maximises vertical space for efficient order picking |

| Photography Studio | Adjustable Height Mobile Rail | Easy height adjustment, smooth-rolling wheels | Accommodates different garment lengths and quick changes |

| Costume Department | Extra-Long, Heavy-Duty Rail | Extended length (6ft+), reinforced centre bar | Manages large volumes of diverse, often heavy costumes |

Ultimately, choosing the right rail comes down to understanding the specific demands of your workspace. A reliable, well-chosen rail is an investment that pays for itself in efficiency, safety, and peace of mind.

The Future of Professional Garment Storage

The humble clothes rail is getting a serious upgrade. Once confined to boutique floors and spare bedrooms, the core principles of strength and durability are now being applied on a massive scale, blurring the lines between retail and high-tech logistics. The future isn't just about holding more clothes; it's about moving them faster and smarter than ever before.

This shift is clearest when you look at the rise of Automated Storage and Retrieval Systems (ASRS). Picture a warehouse the size of a football pitch, but instead of people pushing trolleys, robotic arms glide along vast networks of engineered rails. They can pick a single garment from tens of thousands in mere seconds. The rails in these places have to be incredibly strong and flawlessly manufactured, supporting not just the garments but the relentless motion of the machines themselves.

The Driving Force of Modern Commerce

So, what's behind this massive leap in technology? Two words: e-commerce. We’ve all come to expect next-day delivery and hassle-free returns, and that puts enormous pressure on supply chains to perform. Getting an order wrong or taking too long simply isn't an option anymore. This demand for speed and accuracy is fuelling a quiet revolution in material science and engineering.

Researchers are constantly experimenting with new alloys and composite materials, trying to create rails that are stronger, lighter, and more resistant to wear and tear. In these huge automated systems, every gram saved or bit of friction reduced translates directly into faster operations and lower energy bills.

At its heart, the challenge is the same whether it's for a home rail or a logistics hub: how do you support a huge amount of weight without anything bending or breaking? The technology for solving that problem is just getting much, much cleverer.

The numbers tell the story. The global market for ASRS designed for hanging garments is expected to grow from $1.9 billion in 2024 to $2.05 billion in 2025. It’s a direct response to the need for smarter, just-in-time stock management. You can read more about these market trends to see just how quickly this space is evolving.

From Warehouse to Wardrobe

What’s fascinating is how these industrial trends trickle down to the strong clothes rails you and I can buy. The engineering breakthroughs made for huge logistics operations eventually find their way into the products we use in our shops, studios, and even our homes.

- Better Materials: Those high-strength, lightweight alloys first developed for ASRS? They’ll eventually lead to more durable and easier-to-handle rails for everyone.

- Smarter Designs: The lessons learned from building rails for robots can inspire more ergonomic and efficient designs for people working in a stockroom.

- Tougher Construction: The intense focus on reliability in automated systems forces manufacturers to improve the quality of everything—welds, finishes, castors—across their entire product range.

It all proves a simple but important point: a focus on quality and strength isn't old-fashioned. It’s the foundation of modern garment management, whether you’re talking about a single heavy-duty rail in a tailor’s workshop or a sprawling, automated network in a distribution centre.

Got a Few Questions About Strong Clothes Rails?

Even after going through a detailed guide, a few practical questions often pop up. We get it. So, let's tackle some of the most common queries we hear from customers. Think of this as a final chat to make sure you feel completely confident before you buy.

How Can I Tell If a Rail Is Genuinely Strong Before I Buy It?

The best way is to trust your eyes and hands. Look for physical clues that scream "durability". Pay close attention to the metal gauge and the tube diameter. A genuinely heavy-duty rail isn't shy—it's made from thicker steel (which, confusingly, means a lower gauge number) and has a wider, more substantial frame that feels solid.

The way it’s put together is another dead giveaway. Check the joints where the pieces connect.

- Welded Joints: These are the gold standard. When parts are fused together, you get a single, rigid unit that won't wobble or loosen over time. It’s a clear sign of quality and strength.

- Screwed Fittings: These can be fine, but they need to be robust. Look for heavy-duty bolts, not the kind of flimsy screws you'd find in a flat-pack bookcase.

Lastly, don't be afraid to judge it by its weight. A truly strong rail has a reassuring heft. That weight tells you it’s made from high-quality, dense materials, not some lightweight, corner-cutting alloy.

Are Rails with Wheels as Sturdy as Stationary Ones?

This is a great question, and the answer is a resounding yes—as long as you choose a good one. The sturdiness of a mobile rail comes down to one thing: the quality of its castors (the wheels) and how securely they’re attached to the frame.

A proper heavy-duty mobile rail will have large, industrial-grade castors, often made from rubber or polyurethane, that glide smoothly even under a heavy load. And critically, they must have reliable locking brakes. Once those brakes are on, a top-tier mobile rail should feel every bit as stable as its stationary cousin. The thing to avoid at all costs is cheap, plastic wheels that are just waiting to crack or wobble under pressure.

The best mobile rails are engineered for stability from the ground up. The frame is designed to distribute weight evenly over the castors, ensuring that mobility never comes at the cost of strength.

What's the Best Way to Install a Rail on a Plasterboard Wall?

Mounting anything heavy on plasterboard needs a bit of know-how because the board itself can't take much weight. The golden rule is this: you must anchor the rail into the wooden wall studs sitting behind the plasterboard. Grab an electronic stud finder—it’s the best tool for locating these vertical supports and giving your rail the most secure fixing possible.

What if the studs aren't in the perfect spot for your rail? You’ll need to use specialised plasterboard fixings. For a heavy load, forget standard plastic wall plugs. You’re looking for toggle bolts or hollow wall anchors. These clever fixings expand behind the board, spreading the load over a much wider area and stopping the screws from ripping out.

How Much Weight Can a Standard Heavy-Duty Rail Actually Hold?

Capacities can vary, but a good benchmark for a commercial-grade, strong clothes rail made from industrial steel is somewhere between 100kg and 150kg. Some seriously reinforced models are even rated for loads topping 200kg. The key is to always check the manufacturer's specified weight capacity before you buy. That way, you’ll know for sure it can handle what you need it for, whether that's a full stockroom of denim or your personal collection of winter coats.

At Display Guru, we specialise in providing robust, reliable garment rails that are built for the real world. Our rails are designed to withstand the daily demands of any busy retail shop, studio, or home.

Explore our full range of heavy-duty clothes rails at Display Guru