Cutting Pad for Sewing: Your Guide to Precise, Easy Cuts

Think of a cutting pad for sewing as the professional chopping board of your craft room. It's a special, resilient surface that works hand-in-hand with your rotary cutter to deliver clean, precise cuts every single time. More than just a protective layer, it saves your tabletop from getting damaged and keeps your blade's sharp edge for longer.

The Unsung Hero of Your Sewing Room

Before you even think about threading a needle, the journey to a perfect garment begins on the cutting mat. This humble tool is the foundation of any great sewing project, giving you a stable, reliable surface that sets you up for success from the very first cut. Honestly, trying to use a rotary cutter without a proper mat is not just a bad idea—it’s a recipe for disaster.

The real magic of a cutting mat is in how it works with your rotary blade. As you press down and glide the sharp wheel across your fabric, the mat’s surface gives just enough to allow a clean slice through the material without instantly dulling your blade. This perfect partnership is what makes cutting out patterns so quick and accurate.

Why a Cutting Pad is Non-Negotiable

For anyone serious about sewing, a dedicated cutting pad is an absolute must-have. It’s an investment that pays for itself over and over again. Here’s why you really can’t do without one:

- It Protects Your Furniture: The mat acts as a critical barrier, taking the full force of the rotary cutter. No more deep scratches, nicks, or permanent gouges in your beloved cutting table.

- It Extends Blade Life: Its unique material is designed to be cut into without falling apart, which means your expensive rotary blades suffer far less wear and tear.

- It Improves Cutting Accuracy: Most mats come with printed grids, angles, and measurements. These guides are invaluable for lining up your fabric and making perfectly straight, square cuts every time.

- It Enhances Safety: The surface has a slight grip that stops your fabric and rulers from slipping as you cut, which dramatically reduces the risk of the blade going where it shouldn't.

Of course, having the right tools is only part of the equation. Developing good fine motor skills will also make a world of difference to your accuracy and control. The value of foundational tools like these is clear in the professional world, too. The UK’s garment manufacturing sector has seen a huge revival, with small businesses reporting a massive 128% increase in sales. This kind of growth simply isn't possible without efficient, precise cutting processes.

Ultimately, a great cutting mat is the first step towards creating a well-organised and productive workspace. We explore this topic in more detail in our guide to brilliant sewing room ideas.

Getting to Grips with Self-Healing Mats and Other Types

When you start looking for a cutting pad for your sewing projects, you’ll see the term ‘self-healing’ pop up everywhere. It’s not just a fancy marketing phrase; it’s a specific bit of tech that has made these mats the go-to choice for anyone serious about sewing and quilting. They’re designed to take thousands of cuts without turning into a grooved, fabric-snagging mess.

Think of it like a dense bundle of straws packed tightly together. If you were to push a sharp knife between them, the straws would simply part to make way and then spring right back into place once you pulled the knife out. A self-healing cutting mat works on a very similar principle, just on a microscopic scale.

The Magic Behind a Self-Healing Mat

So, what’s going on inside? These mats are made from several layers of a specialised composite PVC material. The top and bottom layers are tough and provide a non-slip surface to keep everything steady. The real magic, though, is in the dense inner core.

When your rotary cutter blade slices into the surface, it isn't actually chopping through the material. Instead, it’s slipping between tiny, tightly packed particles. Once the blade has passed, the material’s natural memory kicks in, and the particles close up the incision, effectively ‘healing’ it. It's this clever feature that allows a quality self-healing mat to last for years, protecting your blades and giving you a perfectly smooth, precise cut every single time.

Key Takeaway: The layered design of a self-healing mat allows the surface to temporarily part and then reseal. This process dramatically cuts down on wear and tear for both the mat and your rotary cutter blades, making it a far better long-term investment.

A Look at Different Mat Materials

While self-healing mats are definitely the most popular choice, they aren't the only game in town. Knowing the alternatives really helps to show why they come so highly recommended.

Self-Healing PVC Mats:

- Pros: Incredibly durable, they make your blades last longer, often come with handy grid lines, and offer a smooth, trustworthy cutting surface.

- Cons: They have a higher price tag upfront and can be damaged by heat or if you store them improperly.

Basic Foam or Solid PVC Pads:

- Pros: They are very cheap and lightweight, which might appeal to absolute beginners or for something you’ll only use once in a blue moon.

- Cons: These mats don't heal. Every single cut leaves a permanent groove that can trap fluff, catch on your fabric, and even throw your cutter off course, leading to wonky results. They also dull your blades in no time.

In the end, it really comes down to how serious you are about your craft. A basic pad might look like a bargain, but you'll find it needs replacing quickly and can really affect the quality of your work. For anyone who plans to sew regularly, a self-healing mat is the obvious winner for both performance and long-term value.

For a deeper dive, explore our comprehensive guide to sewing cutting mats. Choosing the right foundation is crucial to ensuring your projects start with the accuracy they need. Investing in your workspace like this is one of the smartest moves any sewer can make.

Choosing the Right Mat Size and Thickness

Picking the right cutting pad for your sewing projects isn't just about finding something that fits your table. It’s about choosing a tool that genuinely works with you, improving your accuracy and making the whole process smoother. The size and thickness of your mat are crucial – get it wrong, and you'll quickly find yourself frustrated.

A mat that's too small means constantly shuffling large pieces of fabric around, which is a recipe for wonky cuts. On the flip side, a massive mat that dwarfs your workspace can be just as awkward. It’s all about striking a balance between the projects you love to tackle and the physical space you have.

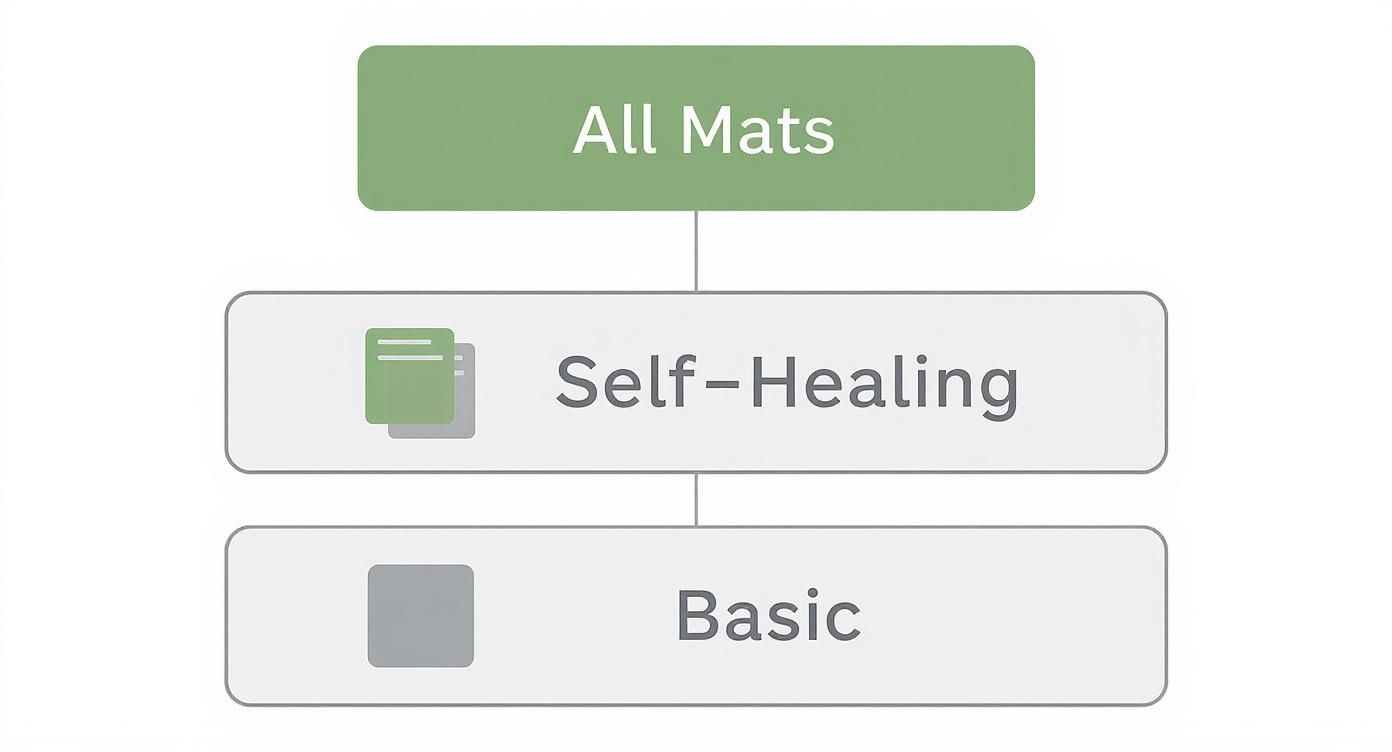

This simple diagram shows the main players in the world of cutting mats.

As you can see, they boil down to two main types: self-healing and basic. For anyone serious about sewing, the self-healing option is really the only way to go for long-term durability.

Finding Your Perfect Mat Size

Cutting mat sizes are often listed by their paper size (A3, A2, A1), but let’s be honest, that’s not always helpful. It’s much more useful to think about what you’ll actually be cutting on it.

-

Small Mats (A3 or 12" x 18"): Perfect for little projects. Think patchwork pieces, appliqué, or doll clothes. They’re also brilliant for taking to workshops because they're so easy to carry around.

-

Medium Mats (A2 or 18" x 24"): This is the sweet spot for many home sewers. It’s big enough to handle pattern pieces like bodices and sleeves, but it won’t completely take over your sewing table. A true all-rounder.

-

Large Mats (A1 or 24" x 36"): If quilting or dressmaking is your passion, a large mat is an absolute game-changer. You can lay out the full width of your fabric straight from the bolt, which saves an incredible amount of time and helps ensure every cut is perfectly straight.

Finding a mat with the right dimensions and features is key. You can explore a variety of dual-sided cutting mats that offer flexibility for different project demands.

Here’s a quick guide to help you match a mat size to your sewing habits.

Cutting Pad Size Guide for Sewing Projects

| Pad Size (ISO) | Dimensions (cm) | Best For | Workspace Suitability |

|---|---|---|---|

| A3 | 29.7 x 42 cm | Small patchwork, quilting blocks, appliqué. | Excellent for small desks or as a portable travel mat. |

| A2 | 42 x 59.4 cm | Cutting garment pieces, medium-sized crafts. | A versatile choice for most standard home sewing tables. |

| A1 | 59.4 x 84.1 cm | Quilting, dressmaking, cutting large fabric lengths. | Ideal for dedicated cutting tables or large workbenches. |

| A0 | 84.1 x 118.9 cm | Professional use, upholstery, full-scale patterns. | Requires a substantial, dedicated professional workspace. |

Choosing the right size is all about honest assessment of your space and the kind of sewing you do most often.

Of course, the surface you cut on is only half the battle. For a deep dive into the furniture that supports it, check out our guide on choosing the best cutting tables for sewing.

Why Mat Thickness Matters

When it comes to cutting mats, thickness equals durability. It’s that simple. While a thinner, cheaper mat might seem tempting, it’s often a false economy as it will wear out much faster and won't protect your table nearly as well.

A thicker cutting pad gives your rotary blade a deeper, more forgiving surface to sink into. This not only provides better protection for your worktop but also massively prolongs the life of the mat’s self-healing surface.

You’ll typically see mats described as having 3-ply or 5-ply construction. The 5-ply mats are the gold standard, featuring a tough inner core that stops the blade from slicing right through. This robust construction also helps the mat stay perfectly flat over time. For any serious hobbyist or professional, investing in a thicker, 5-ply mat is always the smarter long-term decision.

Extending the Life of Your Cutting Pad

A quality cutting pad is a real investment in your craft, but like any good tool, it needs a bit of respect to perform at its best. Thankfully, proper care doesn't take much effort, but it can easily add years to your mat's lifespan. This keeps your surface flat and reliable for countless projects to come.

The most common culprit that wears a mat down is the slow accumulation of tiny fabric fibres. These little bits of lint and fluff get trapped in the self-healing cuts. At first, you won’t even notice, but over time, this debris stops the cuts from closing properly, which compromises that perfectly smooth surface you rely on.

Simple Cleaning and Maintenance

Keeping your mat in top condition is refreshingly simple. You don’t need any harsh chemicals—in fact, they can do more harm than good by damaging the surface. The best approach is always a gentle one.

- For light cleaning: Grab a large, soft pencil eraser and gently rub it over the surface. The eraser does a surprisingly good job of picking up trapped fibres, balling them up so you can brush them away.

- For a deeper clean: If your mat needs a bit more attention, pop it in the bathtub with some cool water and a single drop of mild dish soap. Use a soft-bristled brush to gently scrub the surface, then give it a thorough rinse with more cool water.

- Always dry it flat: After washing, pat the mat down with a soft, lint-free cloth. Then, leave it to air dry completely on a large, flat surface, well away from any direct heat like radiators or sunlight.

Crucial Tip: Never, ever use an iron on or even near your cutting mat. The heat will cause it to warp and bubble in an instant, permanently destroying that essential flat surface and ruining its self-healing magic.

Storage The Right Way

How you store your cutting pad is just as important as how you clean it. Improper storage is the number one reason these mats get warped and damaged, turning an expensive tool into a useless one. The golden rule couldn't be simpler: always keep it flat.

Leaning your mat against a wall, even for a short while, can cause it to develop a permanent bow. Rolling it up is a definite no-no; you’ll find it never quite lies perfectly flat again.

The best solution is to store it completely flat, perhaps under a bed or on a wide shelf. Alternatively, you can hang it using purpose-made clips that grip the entire edge, distributing its weight evenly. You can find more inspiration in our guide to smart sewing room storage ideas.

These tools are central to the UK's thriving textiles industry, a sector which generated approximately £158.6 billion in revenue. From professional design studios to dedicated home crafters, the demand for quality equipment like a reliable cutting pad is always high. Discover more about the UK textiles manufacturing industry's scale and its impact on the tools we rely on every day.

Making an Informed Buying Decision

Choosing the right cutting pad isn't a one-size-fits-all affair. The mat that’s perfect for a weekend quilter tinkering with small projects will be worlds away from what a professional dressmaker needs for high-volume, daily work. The trick is to match the mat’s features to your own sewing habits and creative goals.

For hobbyists, it usually comes down to getting the most bang for your buck. You want a tool that can handle whatever you throw at it, without taking over your entire workspace or wallet. A medium-sized, double-sided mat is often the sweet spot, giving you different grid markings and effectively doubling its lifespan.

Professionals, on the other hand, need to think about durability and pure efficiency. When your time literally is money, features that shave seconds off your workflow are non-negotiable. This often means investing in a large-format mat that can handle an entire width of fabric and is built to withstand constant, heavy use.

Comparing Key Features

To find your perfect match, let's get into the technical details that actually make a difference. Understanding these will help you look past the price tag and invest in a tool that truly serves you well.

- Construction Ply: You’ll often see mats advertised as 3-ply or 5-ply. A 5-ply mat has a tough inner core that stops your rotary blade from slicing straight through. This makes it far more durable and a better guardian for your table. For heavy, regular use, 5-ply is the only way to go.

- Grid and Markings: While a single-sided mat gets the job done, a double-sided cutting pad offers twice the utility. Many have imperial measurements on one side and metric on the other, or even different coloured grids, which is a lifesaver for seeing your markings on both light and dark fabrics.

- Speciality Mats: If you often find yourself working on small, fiddly pieces like quilt blocks, a rotating cutting mat is a game-changer. It lets you turn the mat instead of the fabric, which makes getting those precise cuts so much easier.

There's no doubt that sewing is more popular than ever. In the UK, the sewing machine market brought in USD 116.7 million and is expected to keep growing, showing just how many of us are getting into home crafting. This boom drives the demand for quality gear, including a reliable cutting pad. You can discover more insights about the UK's sewing accessories market to see the trend.

And while a rotary cutter is a must-have, never underestimate the power of traditional tools. Our guide on the vital role of scissors in sewing will help you build a complete and effective toolkit.

Your Cutting Pad Questions, Answered

Even after years of sewing, we all run into little snags with our tools, and the trusty cutting mat is no exception. Getting to the bottom of these common issues is the key to keeping your mat in top shape for years to come. So, let's dive into some of the questions I hear most often.

Is your rotary cutter suddenly skipping stitches or chewing up your fabric? Before you start eyeing your mat with suspicion, take a look at your blade. Honestly, in more than 90% of cases, a dull or nicked blade is the real troublemaker. Pop in a fresh one, and you'll likely find the problem disappears instantly.

If a new blade doesn’t do the trick, your mat might be showing its age with some deep grooves from repeated cuts in the same spot. Even self-healing mats have their limits. Try shifting your cutting to a less-used area of the mat, and get into the habit of rotating it regularly to spread the wear and tear out.

Troubleshooting Common Mat Problems

Some problems need a specific fix to avoid doing permanent damage. Heat, for instance, is the absolute arch-nemesis of your cutting mat.

Never, ever use an iron on or near your cutting mat. The heat will warp it in a heartbeat, melting the surface and completely ruining its flat, self-healing structure. Stick to a proper ironing board or a wool pressing mat for all your pressing needs.

What happens if the damage is already done and your mat is warped? It's a tough situation, but not always a lost cause. Try laying the mat on a perfectly flat floor in a warm room (but not in direct sunlight or near a radiator). Weigh it down evenly with heavy, flat objects like a stack of big books and leave it for a few days. Sometimes, this gentle pressure can coax it back into shape, but prevention is always better than a cure.

At Display Guru, we know that professional-level tools are the backbone of incredible creations. To set up the perfect sewing studio, take a look at our range of professional-grade mannequins and display solutions. Let us help you equip your creative space.