Choosing Cutting Tables for Sewing in the UK

A great sewing project starts long before you even touch your machine. It all begins with a clean, accurate cut, and that's where a dedicated cutting table really shines. It’s not just another piece of furniture; it’s the very foundation of your work, ensuring accuracy, efficiency, and comfort from the get-go.

Why a Dedicated Cutting Table Will Transform Your Sewing

Many of us start out on the dining room table or even the floor. While that’s resourceful, these makeshift surfaces often lead to frustration, wonky cuts, and a sore back. Think of a proper cutting table as the unsung hero of your sewing room—a sturdy, correctly-sized platform that stops fabric from shifting and makes sure your pattern pieces are true from the very start.

This dedicated space is about more than just convenience; it’s about quality control. When your beautiful fabric drapes over the edge of a small table, its own weight can pull and distort it. The result? Skewed cuts that throw off your entire project.

A stable, expansive surface is the single most effective tool for preventing costly cutting mistakes. It allows you to lay out entire pattern pieces flat, ensuring every line is precise and every angle is correct.

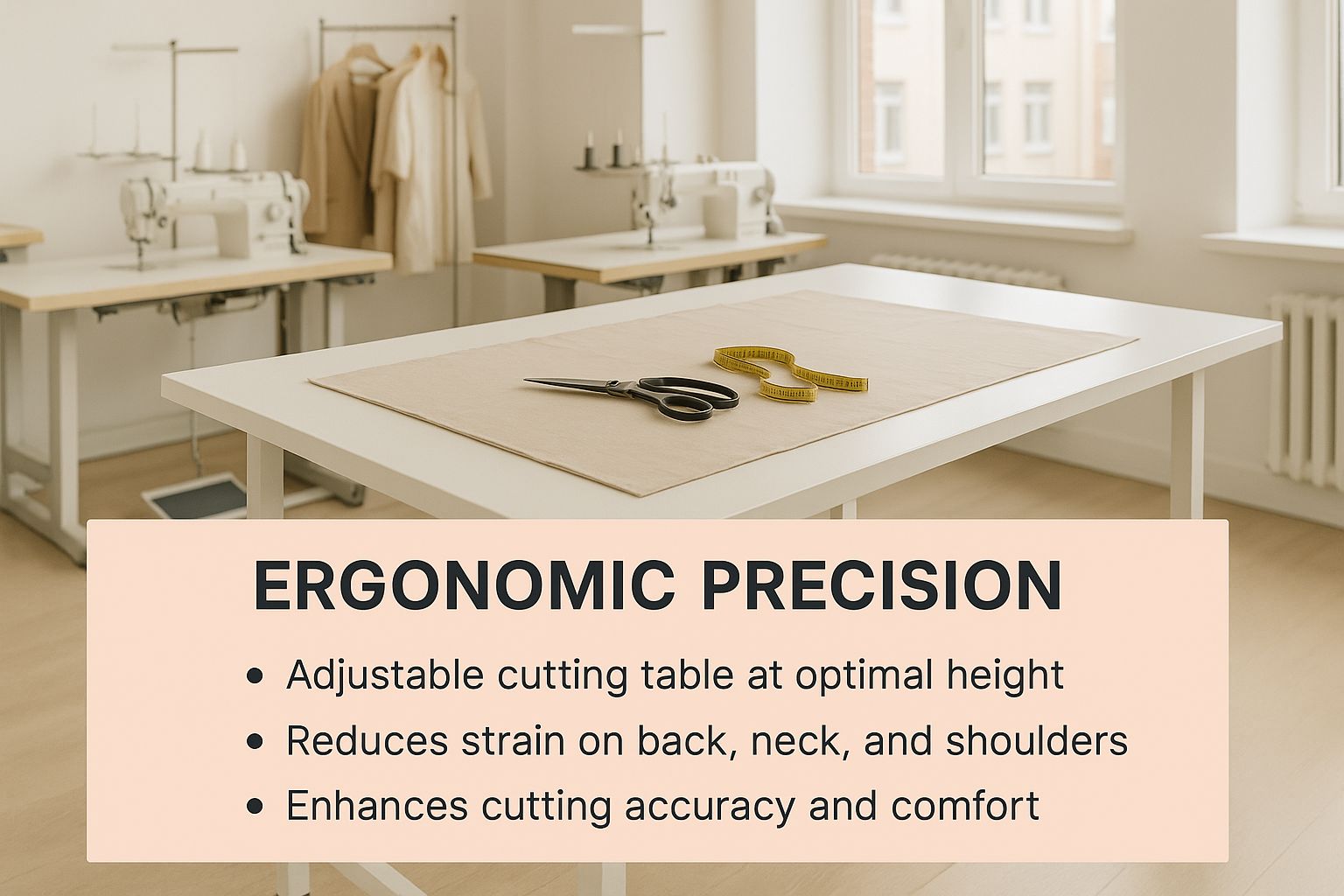

The Impact on Accuracy and Comfort

So, what does a purpose-built cutting table for sewing really give you? Two main things: a large, stable surface and a comfortable working height.

Cutting on the floor or a low dining table forces you to hunch over, which quickly leads to back, shoulder, and neck strain. A table built for the job is set at a height that lets you stand comfortably, maintaining good posture while you work.

This ergonomic benefit makes the whole process more enjoyable and sustainable, especially for larger projects. You'll also find your accuracy skyrockets, which saves fabric, time, and the headache of having to re-cut pieces.

This shift towards better equipment is part of a wider trend. For instance, the UK sewing machine market is growing steadily, with electric machines expected to hold a 46.19% revenue share in 2024. This shows people are investing in precision tools that match their modern machines. You can read more about these UK market insights on Grand View Research.

Investing in the right equipment elevates your craft from a hobby to a more polished, professional practice. To explore the specifics of what makes a great workspace, check out our detailed guide on the ideal sewing and cutting table. Ultimately, a proper cutting table transforms your entire sewing experience by building precision right into your workflow.

Finding the Right Type of Cutting Table for Your Space

Choosing the right cutting table is a bit like selecting the perfect fabric for a garment. What works for a grand ballgown won't be right for a simple cotton t-shirt. The best choice for your sewing space has to fit your room, your projects, and the way you work. Not all cutting tables for sewing are created equal, so let’s break down the main types to find your perfect match.

If you’re lucky enough to have a dedicated studio or a generously sized sewing room, a large, permanent cutting table is the dream. Think of it as the sturdy workhorse of the sewing world. These tables offer a massive, stable surface that won’t budge an inch as you cut, giving you the precision you need for every single project. Their only real downside is their footprint; they need a permanent spot and aren't designed to be moved.

Adapting to Your Environment

For the many of us in UK homes where every square foot counts, a folding cutting table is an absolute godsend. These clever designs give you a surprisingly large workspace when you need it, then fold down neatly to be tucked away in a cupboard or against a wall. While they might not be as rock-solid as a permanent fixture, modern versions are remarkably sturdy and offer a fantastic compromise for sewing in a living room or spare bedroom.

Then we have adjustable-height tables, which are a genuine game-changer for your posture and comfort. Being able to change the table’s height means you can sit for fiddly, detailed tasks and then stand for those long cutting sessions. This flexibility is your best defence against the back and shoulder ache that so many sewers know all too well, making your craft more enjoyable for years to come.

The best workspace is one that adapts to you, not the other way around. An adjustable or multi-purpose table turns a simple piece of furniture into an active partner in your creative process.

Many tables now double up as multi-purpose tables with brilliant integrated storage. Imagine having built-in drawers, shelves, or cubbies right where you need them, keeping your rotary cutters, rulers, and fabric pens organised and close at hand. Combining your cutting surface with storage is a smart, efficient way to get the most out of a smaller room. If you’re looking for more ways to organise your creative corner, you might find some great tips in our guide to sewing room ideas.

To make the decision a little easier, it helps to see the options side-by-side.

Comparing Cutting Table Types for Your Sewing Needs

This table compares the most common types of cutting tables, helping you see at a glance which one best suits your space, projects, and comfort.

| Table Type | Best For | Key Advantage | Main Consideration |

|---|---|---|---|

| Permanent | Dedicated sewing studios with ample room. | Unmatched stability and a large, consistent work surface. | Requires a significant, permanent amount of floor space. |

| Folding | Multi-use spaces or smaller homes. | Excellent space-saving design; folds away when not in use. | Can be less stable than permanent models. |

| Adjustable-Height | Sewers focused on comfort and ergonomics. | Prevents back and shoulder strain by adapting to you. | Often comes at a higher price point. |

| Multi-Purpose | Anyone needing to maximise a small space. | Combines a cutting surface with essential storage. | Storage features may slightly reduce the usable surface area. |

Ultimately, the right table isn't just a surface—it's a tool that supports your creativity, improves your results, and makes the whole process more comfortable.

How to Select the Perfect Table Dimensions

Choosing the right dimensions for your cutting table for sewing is one of the most important decisions you'll make for your sewing space. It's not just about having a flat surface; the right size and height have a massive impact on your comfort, your posture, and ultimately, the precision of your work.

A poorly sized table can be a real pain—literally. One that’s too low will have you hunched over, leading to nagging back and shoulder aches. A surface that’s too small means your fabric is constantly drooping and pulling at the edges, which is a surefire recipe for inaccurate cuts.

The goal is simple: your table should fit you, not the other way around. Let's walk through how to find the dimensions that will make cutting feel less like a chore and more like a seamless part of your creative process.

Finding Your Perfect Cutting Height

The ideal height for a cutting table is all about keeping your posture natural and preventing you from stooping. The easiest way to find your magic number for a standing-height table is what I call the "elbow rule." It's surprisingly simple.

- Stand up straight: Position yourself with your feet flat on the floor, wearing the shoes you’d normally have on while you work.

- Bend your arm: Bend your dominant arm to a 90-degree angle, almost as if you’re about to shake hands.

- Measure down: Your perfect table height is right where your wrist rests, or roughly 8-10 centimetres (3-4 inches) below your bent elbow.

This little test ensures your shoulders can stay relaxed and you can apply steady, even pressure with a rotary cutter without straining your back or neck. For most people, this works out to a table height somewhere between 86 cm and 96 cm (34-38 inches).

An ergonomic workspace is a sustainable one. Setting your table to the correct height means you can work for longer periods with greater focus and comfort, dramatically improving the quality of your finished garments.

Choosing the Right Width and Length

Once you've nailed down the height, the next thing to consider is the surface area. A table that’s too narrow or too short will force you into a constant dance of re-folding and shifting your fabric, which is where cutting errors love to creep in.

Here are some good rules of thumb:

- Width: Most bolts of fabric are a standard 112 cm (44 inches) wide, but dressmaking and quilting fabrics can often be wider. To give yourself a comfortable buffer on either side, I'd suggest aiming for a table width of at least 122 cm (48 inches).

- Length: A length of 183 cm (72 inches) is a fantastic starting point for most sewists. This gives you enough space to lay out a good length of fabric, making it much easier to cut large pattern pieces for items like dresses or trousers in one clean pass.

At the end of the day, the best cutting tables for sewing offer a generous, uninterrupted surface that fully supports your material from edge to edge. This prevents any distortion and helps you make every cut as accurate as the last. If you want to dive deeper into what the professionals use, this guide to the industry-standard pattern cutting table is a great resource.

Essential Materials and Features for Your Cutting Table

The heart of any cutting table lies in its construction. Think of it this way: the material is the foundation of your entire cutting process. A wobbly or uneven surface will only lead to frustration and inaccurate cuts, so getting this part right from the start is non-negotiable.

The tabletop material itself is what you'll be interacting with day in, and day out. While solid wood is a timeless, incredibly sturdy option, it often comes with a premium price tag. For a fantastic balance of performance and affordability, many turn to Medium-Density Fibreboard (MDF), which offers a perfectly smooth and stable surface. Laminates are another popular choice, giving you a tough, scratch-resistant finish that's a breeze to keep clean.

But a great cutting table is more than just a flat surface. Certain features can elevate it from a simple piece of furniture into a powerhouse for your sewing projects. Knowing what to look for will help you find a table that genuinely supports your craft.

Core Features That Boost Functionality

The real magic is in the details. These are the thoughtful additions that streamline your workflow, sharpen your precision, and ultimately make sewing more enjoyable.

Here are the key features you'll want to keep an eye out for:

- Lockable Castors: These wheels are a game-changer. They give you the flexibility to move the table for cleaning or rearranging your room, but with a flick of a lever, they lock down for absolute stability. No more shifting or wobbling while you’re making a critical cut.

- Integrated Measuring Grids: A grid printed directly onto the tabletop is incredibly handy. It lets you square up fabric and make quick, straight cuts without constantly grabbing for a tape measure or quilting ruler.

- Built-in Storage: A table with shelves, drawers, or cubbies is a massive win, especially if you're tight on space. It keeps your rulers, rotary cutters, and other tools organised and close at hand, leaving your main workspace clear for fabric.

A well-equipped cutting table isn’t just furniture; it’s a command centre for your creativity. Features like integrated storage and mobility directly support a more efficient and organised sewing practice.

The Bigger Picture: Materials in UK Industry

The need for a solid, dependable cutting table isn't just a concern for home sewers. These surfaces are the bedrock of the UK's professional textile industry, a sector where precision and efficiency are everything. From small-scale designers to large garment manufacturers, the quality of the cut starts here.

It's a testament to their importance that this industry, which relies so heavily on quality cutting surfaces, contributed a staggering £62 billion to the UK GDP as of October 2023. This industrial context really underlines how vital a well-designed, stable cutting surface is for achieving professional-level results, no matter the scale.

Smart storage is just as crucial for the pros as it is for us at home. An organised space equals a more focused and productive workflow. If you're looking for clever ways to get your own creative space in order, our guide on sewing room storage ideas has some fantastic tips. By choosing a cutting table with the right materials and features, you're not just buying furniture—you're investing in a tool that will elevate your craft for years to come.

Setting Up and Maintaining Your Workspace

So, your new cutting table has arrived. That's the exciting part. But getting it set up properly is what truly turns it from a simple piece of furniture into the workhorse of your sewing room. Taking a little time now to get the placement right and commit to some simple care routines will ensure it serves you well for countless projects to come.

First things first, let’s talk location. The best spot for your table is one with plenty of good light. If you can, place it near a window to take advantage of natural daylight, which is unbeatable for judging colour and detail. But don't rely on that alone; add a good task lamp to eliminate shadows. Your eyes will thank you, especially during late-night sewing sessions.

Once you’ve found the perfect spot, it’s time to get it level. Don't skip this step! Grab a spirit level and check the surface from every angle. Adjust the feet or lock the castors until it's perfectly flat and stable. A wobbly or tilted table is a recipe for disaster, causing fabric to slip and leading to inaccurate cuts. Precision is the whole point of having proper cutting tables for sewing, and that starts with a solid foundation.

Keeping Your Table in Top Condition

Looking after your table isn't difficult, but it does require a bit of mindful habit-forming. Think of it as protecting your investment.

The golden rule? Always use a self-healing cutting mat. This is non-negotiable. Taking a rotary cutter or craft knife directly to the tabletop is a surefire way to score and ruin the surface forever.

A self-healing mat is your table's best friend. It not only shields the surface from damage but also grips the fabric and helps your rotary blades stay sharp by absorbing the cuts.

To keep your entire workspace in great shape, just fold these simple tasks into your routine:

- Clean it Down: Fabric creates a surprising amount of lint and dust. Wipe the surface regularly with a soft, damp cloth. For tougher spots on laminate, a gentle cleaner usually does the trick, but always check what the manufacturer recommends first.

- Check for Wobbles: Every so often, give the table a gentle shake and tighten any bolts on the legs or frame that might have worked themselves loose. If you have castors, test the locking mechanisms to ensure they're still holding firm.

- Avoid Spills: Be mindful of placing mugs or glasses directly on the table. Moisture can cause water rings or even swelling on wood and MDF surfaces. A coaster is a simple fix.

By making these small actions part of your process, you’ll keep your cutting table looking and performing its best. If you're looking for more ideas on creating an efficient and inspiring space, you might find our guide to sewing room organisation helpful.

The Bigger Picture: Cutting Tables in UK Industry

While a great cutting table can revolutionise a home sewing room, its role becomes absolutely critical in the professional world. These surfaces are more than just furniture; they are the foundation of the UK's bustling textile and garment industry, where every cut has to be perfect. In a commercial setting, every centimetre of fabric is money, and every minute saved in the cutting room directly boosts the bottom line.

Think about the stability, height, and surface area you value in your own sewing space. Now, imagine those qualities are no longer just nice-to-haves, but non-negotiable requirements for a business to succeed. The professional world takes these fundamentals and pushes them to a whole new level.

From Manual Precision to Automated Power

In large-scale manufacturing, the familiar rotary cutter and mat are replaced by highly specialised, often computer-driven machinery. Picture enormous air-flotation tables that let a single operator glide huge, heavy stacks of fabric into place effortlessly. Then there are the computer numerical control (CNC) cutters, which follow digital patterns to slice through hundreds of layers of material at once with incredible speed and flawless accuracy.

These industrial cutting tables for sewing are built for one purpose: achieving maximum output without a single compromise on quality. They're engineered to endure constant, heavy-duty use and fit seamlessly into a production line that moves from fabric spreading, to cutting, and then onto the sewing floor.

At its heart, the principle is the same whether you're at home or in a factory: a stable, flat surface is essential for an accurate cut. The industrial setting simply uses technology to achieve this on an immense scale.

This professional context really drives home the value of a solid cutting setup at any level. The demand for skilled people who understand this fundamental process remains high. In fact, data from January 2025 showed 2,369 job openings for textile process operatives in the UK—a role where preparing fabric for cutting is a key responsibility. You can discover more about these employment trends and what they mean for the industry.

Lessons from the Professionals

Seeing how the pros operate offers a valuable perspective for any home sewer. It highlights why investing in a sturdy, well-proportioned cutting table is so important for your own craft. It’s the one piece of equipment that directly enables you to achieve the highest standards of workmanship.

By choosing a table that lets you work comfortably and precisely, you’re adopting the very same principles that drive quality and success across the UK's fashion and textile sector. It all comes down to respecting your materials and the process, right from the very first cut.

Frequently Asked Questions About Sewing Cutting Tables

It's completely normal to have a few questions when you're looking for the right cutting table. After all, it’s a big part of your sewing setup, and getting it right from the start can make a world of difference. Let's walk through some of the most common queries I hear from fellow makers.

Think of this as a final conversation to clear up any lingering doubts. Making an informed choice now means you'll end up with a table that feels like a true partner in your craft, not a daily frustration.

What Is the Best Height for a Sewing Cutting Table?

The perfect height comes down to one thing: your comfort. You want a table that saves your back, not strains it. A good rule of thumb is to find a surface that sits around hip-bone level.

For a more tailored measurement, stand up straight and bend your elbow to a 90-degree angle, as if you were about to shake someone's hand. The ideal tabletop height is right where your wrist hangs. For most people, this falls somewhere between 86 cm and 96 cm (34-38 inches). If you can, investing in an adjustable-height table is a brilliant move; it gives you the freedom to fine-tune the height perfectly or even switch between standing and sitting.

Can I Just Use My Dining Table to Cut Fabric?

Many of us started out on the dining room table, so it's a tempting shortcut! But honestly, it's not a great long-term plan. Dining tables are built for sitting, which means they're almost always too low for cutting fabric while standing. You'll inevitably find yourself hunched over, which is a recipe for an aching back.

On top of that, a dining table's finish is rarely up to the task. One slip of a rotary cutter or a stray pin can leave a permanent mark. A dedicated cutting table, set to a comfortable height, is one of the best upgrades you can make for your sewing—both for your body and your work.

A self-healing cutting mat is absolutely essential. It not only protects your table's surface from damage caused by rotary cutters but also extends the life of your blades by providing a forgiving surface to cut into.

Is a Self-Healing Cutting Mat Really Necessary?

Yes, a thousand times yes! I'd go so far as to say it’s non-negotiable. Think of a self-healing mat as the ultimate shield for your cutting surface. It’s designed to absorb the pressure from a sharp rotary blade, preventing those deep, ugly gouges that would ruin a standard tabletop.

But it does more than just protect your furniture. That slightly soft surface is also kinder to your blades, helping them stay sharper for much longer. Plus, most mats come with a printed grid, which is incredibly handy for lining up fabric and making sure your cuts are perfectly straight. It’s an accessory that pays for itself by protecting your table and improving your accuracy.

At Display Guru, we understand that a professional-grade setup is key to achieving beautiful results. Explore our range of tools and furniture designed to support your creative process from the first cut to the final stitch. Find the perfect foundation for your sewing studio at https://www.displayguru.co.uk.