Choosing Your Ideal Pattern Cutting Table

A professional pattern cutting table is the heart of a sewing studio. It's the dedicated, stable, and spacious surface where the blueprint for a garment comes to life. Far more than just a piece of furniture, it’s the tool that ensures every cut is precise, laying the groundwork for a beautifully constructed piece.

What Makes a Pattern Cutting Table Essential?

Picture a top chef at work. They wouldn't dream of preparing a Michelin-starred meal on a wobbly, cramped side table. They need a large, solid prep station to lay out, measure, and slice every ingredient with absolute control. For a sewer, designer, or tailor, a pattern cutting table plays the exact same role. It’s the professional stage where your creative vision meets technical accuracy.

Anyone who has tried to cut metres of fabric on the dining room table—or worse, the floor—knows the frustration well. These surfaces are rarely big enough, perfectly flat, or at a comfortable working height. The inevitable result is fabric that shifts, cuts that go askew, and pattern pieces that just refuse to line up. A dedicated cutting table makes all those problems disappear.

The Foundation of Precision and Comfort

At its core, a cutting table gives you an unshakeable, expansive surface. This allows you to lay out your entire fabric width and pattern pieces without anything bunching up or distorting. That stability is non-negotiable if you want to achieve clean, straight lines and perfectly formed curves. When every piece is cut correctly from the start, you stand a much better chance of them fitting together seamlessly later on.

It's not just about accuracy, either. These tables are built with ergonomics in mind. Spending hours hunched over a low surface is a recipe for back and shoulder pain. A proper cutting table is usually set at a comfortable standing height, which dramatically reduces physical strain and lets you focus completely on your craft.

A great pattern cutting table isn't a luxury; it's a fundamental investment in quality. It prevents the subtle errors that can compromise an entire project, ensuring the final garment reflects the skill and vision behind it.

More Than Just a Flat Surface

The benefits go far beyond just cutting. A good table quickly becomes the central hub of your entire creative space. It’s the perfect spot to:

- Draft and Alter Patterns: The large, smooth area is ideal for drawing, tracing, and modifying your patterns with the precision they demand.

- Pin and Mark Fabric: Having enough room means you can pin pattern pieces securely without the fabric hanging over the edge, which can pull the grainline out of true.

- Organise Your Workflow: Many tables come with built-in storage, keeping essential tools like rotary cutters, shears, rulers, and chalk right where you need them.

Ultimately, this one piece of equipment can transform your sewing process from a constant struggle into a smooth, efficient workflow. Improving your setup is a key step, and effective sewing room organisation can make a world of difference in your productivity and enjoyment. A dedicated pattern cutting table is the cornerstone of that organisation, creating a zone for accuracy that elevates every single project you tackle.

Deconstructing a High-Performance Cutting Table

To really understand what sets a brilliant pattern cutting table apart, you have to look past its simple form and see its individual parts. Think of it like a bespoke suit; the real quality is in the materials and the craftsmanship. Every single element, from the surface you cut on to the frame holding it all up, has a direct say in your efficiency, comfort, and the precision of your work.

Once you know what makes a table tick, you gain a practical framework for judging any model you come across. You can quickly spot the difference between a basic, wobbly table and a high-performance workspace designed for serious work. Let's pull back the curtain and look at the anatomy of a first-class cutting table.

The Crucial Cutting Surface

This is where the magic happens, so the material of your tabletop is absolutely critical. It needs to be perfectly flat, completely smooth, and tough enough to handle the daily pressure of rotary cutters and shears without complaining.

-

Laminate over MDF: This is a hugely popular and practical option for a reason. It features a Medium-Density Fibreboard (MDF) core with a tough laminate finish. The laminate gives you that smooth, snag-free surface for fabric to glide over, while the MDF core provides fantastic stability. It’s a smart, cost-effective choice that balances performance with durability.

-

Solid Wood: There's no denying the beauty of a solid wood table. It brings a classic warmth to a studio and is incredibly sturdy. However, wood needs a bit more care to stop it from warping or getting scratched, and it can be a significant investment. You also have to consider the natural grain, which might not be perfectly suited for every single task.

-

Self-Healing Mats: If you live by your rotary cutter, a large, professional self-healing mat is less of a luxury and more of an essential. These are usually laid over a sturdy base to create the ultimate cutting station. They do an amazing job of protecting both your blade and the table, all while "healing" from cuts to maintain a perfectly smooth surface.

The right surface is like a silent partner in your creative work. A smooth, dependable top means you can focus entirely on the accuracy of your cut, not on battling a snagging or uneven workspace.

The Supporting Frame

If the surface is the stage, the frame is the foundation. Its one job is to provide unshakeable stability—no wobbling, no shifting, no nonsense. The two most common materials for this are steel and wood, and each has its own strengths.

A steel frame offers exceptional strength and rigidity, which is why you see them everywhere in professional and industrial workshops. These frames are typically powder-coated for extra durability and can handle enormous weight without flexing. This robust build guarantees your table stays level and steady, even with heavy bolts of fabric on it.

On the other hand, a wood frame has a timeless appeal and delivers solid, reliable performance. When it's properly built with good joinery, it can be just as stable as steel and last a lifetime. While it might be heavier, a wooden frame can be a beautiful piece of furniture in its own right, perfectly suiting a home studio or a boutique sewing room.

Features That Enhance Workflow

Beyond the core materials, a few clever features can turn a simple table into an ergonomic and organised dream.

- Adjustable Height: This might just be the most important feature for your long-term comfort. Being able to set the table to your perfect height for standing work is a game-changer for preventing back strain and improving your posture.

- Integrated Storage: Shelves, drawers, or cubby holes built right into the frame are brilliant for keeping your tools organised and close by. It keeps your main work surface clear and makes your whole process feel more fluid.

- Foldable Design: For anyone tight on space, a foldable pattern cutting table is a fantastic solution. These clever designs give you that huge, functional workspace when you need it, and then let you reclaim your floor space when you're done.

Thinking about these elements is a key part of setting up a workspace that truly works for you. For more inspiration, why not explore our complete guide to sewing room ideas for spaces of every size?

The Role of Cutting Tables in the UK Garment Industry

It’s easy to overlook the humble cutting table, but to do so would be a huge mistake. Far from being just another piece of studio furniture, the pattern cutting table is the unsung hero of the UK’s vibrant garment industry. It's the dependable workhorse you'll find in every professional design studio, bustling factory floor, and bespoke tailor's workshop across the country. This is where the magic begins—where creative vision starts its journey into a tangible garment.

The precision you get from a professional-grade cutting table isn't just a nice-to-have; it's a commercial necessity. In an industry where standards are everything, from Savile Row tailoring to the fast-paced world of high-street fashion, there’s simply no room for error. A perfectly flat, stable, and spacious cutting surface ensures every piece of fabric is cut with total accuracy. This single step minimises costly mistakes and material waste, directly influencing the quality of the final garment and protecting the reputation that makes UK fashion a global powerhouse.

The Engine Room of British Fashion

The scale of the industry these tables support is genuinely immense. They are fundamental tools within a sector that acts as a major economic engine for the United Kingdom. The precision and efficiency they provide are directly linked to the country’s manufacturing output and its celebrated position on the world stage.

Think about the workforce behind that prestigious "Made in Britain" label. The UK fashion and textiles industry employs an incredible number of skilled professionals—approximately 500,000 people in total across manufacturing, wholesale, and retail. Within manufacturing alone, there are 88,000 jobs directly involved in creating garments, and the pattern cutting table is indispensable to every single one of them. You can explore more about the UK fashion ecosystem and its economic contributions.

This solid foundation supports a vast apparel market, forecast to generate revenue approaching £85.85 billion. It’s one of the largest in the world. From independent designers just starting out to large-scale manufacturers, the cutting table is where that value is first created.

A professional pattern cutting table is more than a tool—it is the bedrock of productivity. It allows UK artisans and manufacturers to translate creative designs into tangible, high-quality products that compete on a global scale.

From Small Studios to Industrial Operations

The role of the cutting table evolves with the size of the business, but its core importance never fades.

-

For the Independent Designer: It’s a multi-functional hub for drafting, cutting, and assembling prototypes. A stable surface is absolutely essential for playing with complex designs and nailing the perfect fit before committing to a final pattern.

-

For the Small Production Studio: As orders begin to pile up, an inadequate cutting table quickly becomes a bottleneck. A large, durable table lets you lay out multiple patterns at once, streamlining the cutting process and boosting output without ever compromising on quality.

-

For the Large-Scale Manufacturer: In an industrial setting, these tables are part of a high-speed production line. Often paired with automated cutters, their absolute stability and size are critical for maximising efficiency and ensuring flawless consistency across thousands of garments.

No matter the context, the pattern cutting table is a professional asset. It empowers everyone, from solo creators to entire factory floors, to uphold the high standards of craftsmanship that define the UK garment industry. It's the quiet link between a simple piece of equipment and the nation's economic strength and creative excellence.

Finding the Right Pattern Cutting Table for Your Space

Choosing the right pattern cutting table is easily one of the most important decisions you'll make for your creative space. This isn't just about buying furniture; it's an investment in a core tool that will define your workflow, your comfort, and ultimately, the quality of your finished pieces. Get it right, and the table feels like a seamless part of your process. Get it wrong, and it’s a source of daily frustration.

The trick is to strike a sensible balance between your dream setup and the real-world constraints of your room and budget. Think of it like planning a new kitchen layout. You have to measure the available footprint, consider how you’ll move around the space, and decide which features are absolute must-haves. In the same way, your cutting table needs to fit both your physical space and your creative ambition.

Matching the Table to the User

Let's be clear: there's no single "best" table for everyone. A home hobbyist who enjoys sewing on weekends has completely different needs from a small business owner churning out orders from a dedicated studio. The first step is to honestly assess who you are as a maker.

- The Hobbyist: If sewing is your passion and you work in a room that doubles as a living space, a compact, foldable design is your best friend. These tables offer a surprisingly generous work surface when you need it but can be tucked away neatly when you don't.

- The Small Business Owner: For those running a creative business from a home studio or small workshop, a large, permanent table is non-negotiable. Here, stability, a durable surface, and integrated storage are the top priorities to handle a steady flow of work.

- The Industrial Producer: In a large-scale workshop or factory setting, the game changes entirely. The focus shifts to maximum size and sheer toughness. These environments rely on enormous, heavy-duty tables, often several metres long, built to withstand constant, punishing use.

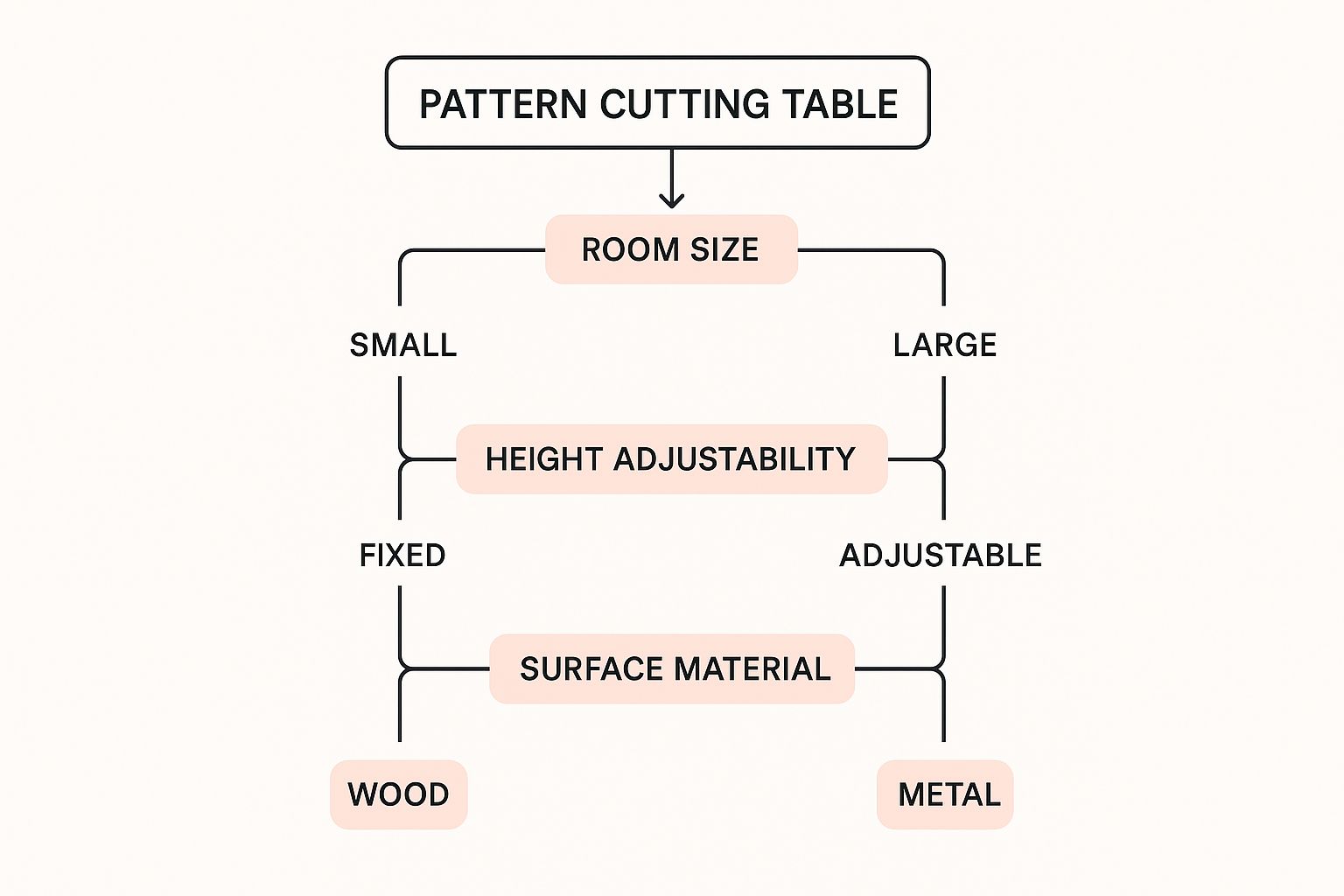

This infographic can help you visualise how your needs translate into the right features.

As the decision tree shows, factors like your available space and your own physical comfort directly point toward the best type of table for you.

A Practical Comparison of Cutting Tables

To help narrow down your choice, I’ve put together a simple table comparing the main options out there. Use it to see how the different types stack up against each other, making it easier to align your needs with the features and price points you can expect.

Comparing Pattern Cutting Table Options

| Table Type | Best For | Key Features | Pros | Cons | Approx. Price (UK) |

|---|---|---|---|---|---|

| DIY/Repurposed | Hobbyists with tight budgets or unique space requirements. | Customisable size, low initial cost. | Highly affordable, can be tailored to exact dimensions. | May lack stability, requires time and skill to build. | £30 - £150 |

| Foldable/Compact | Small spaces, multi-purpose rooms, occasional use. | Hinged leaves, collapsible frame, lightweight. | Saves space, easy to store and move. | Can be less stable than fixed models, smaller surface area. | £100 - £400 |

| Fixed Professional | Dedicated studios, small businesses, frequent use. | Sturdy steel or wood frame, large surface, integrated storage. | Extremely stable, durable, maximises workflow efficiency. | Requires significant dedicated space, heavy. | £400 - £1,200+ |

| Height-Adjustable | Anyone prioritising ergonomics, shared workspaces. | Electric or manual lift mechanism, memory presets. | Reduces back strain, perfect for standing and sitting tasks. | Higher cost, mechanical parts may need maintenance. | £500 - £2,000+ |

This breakdown should give you a clear starting point. From here, you can dig deeper into specific models. For a closer look at what's on the market, exploring a good guide to the best sewing and cutting table options can offer some excellent recommendations.

A word of advice I always give: avoid buying a table that only fits your current projects. If you can, always choose a solution that gives you some room to grow. It will save you from a costly and disruptive upgrade later on.

By taking the time to carefully evaluate your space, your budget, and how you truly work, you can confidently invest in a pattern cutting table that will serve as the reliable foundation for your creativity for many years to come.

How Technology Is Reshaping the Cutting Surface

The world of sewing and garment making is seeing a genuine shift, one powered by digital tools and intelligent machines that introduce a new calibre of accuracy to the craft. As our equipment gets smarter, the humble pattern cutting table is quietly stepping into its most critical role yet. It’s no longer just a passive surface; it's becoming an active partner in a high-precision workflow.

With the rise of digital patterns, projectors, and computerised sewing machines, our expectations for what's possible have been raised. These tools promise flawless execution, but that promise crumbles if the very first step—the cut—is off. Think about it: a top-of-the-line sewing machine programmed for perfect seams is completely undermined if the fabric pieces it’s fed are misshapen because they were cut on a wobbly or uneven surface.

The New Standard of Stability

Modern tech demands an uncompromisingly flat and stable foundation. It's not just a 'nice to have' anymore. When you use a projector to cast a digital pattern directly onto your fabric, even the slightest dip or wobble in the table can distort the projected lines, leading straight to cutting errors. A high-performance pattern cutting table is what ensures that projected image stays true, translating a digital concept into a perfectly cut physical piece.

This growing need for precision tools is clearly reflected in the market. In the UK, the sewing machine market—a great indicator for the demand for quality work surfaces—generated around USD 116.7 million in revenue. Fuelled by the popularity of advanced computerised models, this figure is expected to climb to USD 136.3 million by 2030. You can learn more about these sewing machine market trends and see just how deeply technology is shaping the industry. The trend is obvious: as makers invest in better machines, a professional-grade cutting surface becomes non-negotiable.

A Partner in Efficiency and Waste Reduction

Beyond pure accuracy, today’s pattern cutting table is also a key player in workshop efficiency. As digital tools accelerate the design and sewing phases, the cutting stage can’t afford to be a bottleneck. A large, well-organised table makes for faster, more streamlined batch cutting, helping creators meet demand without ever compromising on quality.

What’s more, precision cutting is a direct path to sustainability. When every piece is cut correctly the first time, you dramatically reduce the offcuts and costly mistakes that end up in the bin.

In a modern sewing studio, the pattern cutting table is no longer just furniture. It is the silent guarantor of quality, bridging the gap between digital design and physical creation, ensuring that technological potential is fully realised.

This connection between technology and the physical workspace is genuinely changing how garments are made. By providing that essential foundation of stability and precision, the modern pattern cutting table ensures that every pound spent on advanced equipment pays off. It gives designers and sewists the power to work faster, smarter, and with complete confidence in their final product.

Setting Up Your Table for Peak Performance

So, your new pattern cutting table has arrived. It’s a great moment, but getting it out of the box is just the start. How you set it up is what really transforms it from a simple piece of furniture into the heart of your workspace. It’s less about just following instructions and more about thinking through placement, getting it perfectly level, and building good habits that will protect your investment for years.

Taking the time to get these first steps right is what sets you up for success. It ensures every cut is precise, your workflow feels effortless, and you can work comfortably for hours on end. Think of it as laying the proper foundation for every project you'll create on it.

Assembly and Optimal Placement

First off, actually read and follow the assembly instructions. It's tempting to jump ahead, but manufacturers have specific reasons for their steps, usually to do with long-term stability. Once it’s built, the next big question is where to put it.

Don't just stick it in the nearest empty space. Think about where it will work best for you. Great lighting, for instance, is completely non-negotiable. If you can, place the table near a window to catch natural light, but always back this up with excellent, shadow-free overhead lighting. You absolutely have to see every single pattern line clearly; bad light is a fast track to cutting mistakes.

You also need to think about the physical flow of the room. Can you walk around all four sides of the table without bumping into things? You'll need that access, especially when you’re wrestling with a massive piece of fabric. This is a basic principle of smart studio design. For more tips on this, our guide to sewing room organisation ideas is packed with practical advice.

After assembly, do this one thing before all else: make sure the surface is perfectly level. Grab a spirit level and check it both lengthwise and widthwise. A table that’s even slightly off-kilter can cause your fabric to shift and stretch, quietly sabotaging the accuracy of every cut you make.

Maintaining Your Work Surface

Your tabletop is going to see a lot of action, so a little ongoing care goes a long way. The right approach really depends on what your table is made of.

-

Laminate Surfaces: These are generally low-maintenance. A regular wipe-down with a soft cloth and a gentle cleaner is all you need. Just stay away from abrasive pads that could scratch the finish.

-

Wood Surfaces: A beautiful wooden top might need a bit more love. To stop it from drying out or cracking over time, you may need to treat it occasionally with a good quality wood oil or wax. This keeps the surface smooth and protected.

-

Self-Healing Mats: Keeping a self-healing mat clean is the key to its long life. Wipe it down with a damp cloth and some mild soap to get rid of all the tiny fibres and dust that build up. Crucially, store it flat and keep it away from direct sunlight or heat, which can cause it to warp.

Building these simple setup and maintenance habits into your routine is what will keep your pattern cutting table in prime condition. It's a small investment of your time that pays off massively in the quality of your work and the simple joy of using a tool that works perfectly.

Your Pattern Cutting Table Questions Answered

So, you understand what a pattern cutting table is in theory, but how does that translate to your actual workspace? Practical questions always pop up when you're trying to find the perfect setup. Let's tackle some of the most common queries I hear from designers and home sewers.

What Is the Ideal Height for a Cutting Table?

The perfect height for a pattern cutting table really comes down to one thing: ergonomics. You want a table that works with your body, not against it.

For standing work, the sweet spot is a surface that sits roughly at your hip bone. This height allows you to stand up straight, keeping your spine neutral while you lean over your fabric. You can extend your arms to cut without hunching your shoulders or straining your back – a real lifesaver during those long cutting sessions.

A quick way to check? Stand next to the table and rest your hands flat on the surface. If your elbows are bent at a comfortable 90-degree angle, you've pretty much nailed it.

Key Takeaway: There's no one-size-fits-all answer here; it’s all about your height. An adjustable table is the gold standard, but for a fixed-height one, aiming for that hip-bone level will make a world of difference to your comfort and posture.

Can I Just Use My Dining Table?

Look, we've all been there. In a pinch, the dining table can seem like a convenient option. But honestly, it's a temporary fix that creates more problems than it solves.

Dining tables are designed for sitting, which means they are almost always too low for cutting comfortably while standing. A few hours spent stooped over like that is a recipe for a sore back. They often aren’t wide enough for a full bolt of fabric either, so you end up shuffling the material around, which is a fast track to inaccurate cuts.

Plus, do you really want to risk gouging your lovely family table with pins, chalk marks, or a slip of the rotary cutter? A dedicated cutting table protects your furniture and gives you a sturdy, reliable surface built for the job.

How Can I Create a Large Cutting Area in a Small Room?

This is the classic dilemma for so many of us! Don't worry, a small room doesn't mean you have to compromise on your cutting space. You just need to be a bit clever.

A foldable pattern cutting table is probably the most popular solution for a reason. It gives you a huge, stable workspace when you need it and then neatly tucks away when you're done.

Another great trick is to place two smaller tables or even a couple of sturdy cabinets of the same height next to each other. You can then lay a large self-healing mat across the top to join them, creating one seamless, modular surface. Thinking ahead is key, and using a good sewing project planner can really help you organise not just your projects, but your physical workspace too.

By thinking through these common challenges, you can create a cutting area that’s not just functional, but genuinely a pleasure to work in.

At Display Guru, we're here to help you build the creative workspace you deserve. From professional garment rails to keep your projects organised to tailors' dummies for achieving that perfect fit, we support every part of your journey. Explore our full collection at https://www.displayguru.co.uk.