The Ultimate Guide to a Clothes Rail Strong Enough for Any Wardrobe

Ever wondered what separates a flimsy clothes rail from one that can handle a packed retail floor? It’s not just about looks. Think of it like building a house—without a solid foundation and a sturdy frame, the whole thing is at risk. The very same principles apply here.

A genuinely strong clothes rail is an engineered system, where every single component has a vital job to do. Whether you're a retailer, a tailor, or just organising your home, getting your head around this anatomy is the key to making a smart investment that lasts.

With the UK's clothing retail industry expected to hit revenues of £50 billion by 2025, the need for display infrastructure that can keep up has never been greater. Your rails need to be stronger and more adaptable than ever.

The Blueprint for a Truly Strong Clothes Rail

So, what should you actually be looking for? To spot a quality product, you need to focus on three fundamental elements that all work together.

- Load Distribution: This is all about how weight is spread across the rail. A well-designed rail distributes the load evenly, stopping stress from building up in one spot—usually the centre—which is where most rails buckle and fail.

- Joint Integrity: The points where the vertical supports meet the horizontal bar are absolutely critical. Weak joints, a common feature on cheaper models, will wobble and eventually give way under pressure. You want to see properly welded connections or heavy-duty screw fittings that create a rigid, unshakeable frame.

- Material Gauge: The thickness of the metal tubing is a direct measure of its strength. A thicker gauge means greater resistance to bowing and bending, ensuring the rail keeps its shape even when it's groaning under the weight of heavy garments like winter coats or piles of denim.

A truly strong clothes rail is an engineered system, not just a simple bar. Its ability to perform depends on how well its design manages force, how securely its parts are connected, and the inherent strength of the materials used in its construction.

Let's break down these core components into a quick-reference guide.

Key Strength Indicators at a Glance

This table summarises the essential factors that determine the strength and durability of a clothes rail, helping you make a more informed choice.

| Component | Why It Matters for Strength | What to Look For |

|---|---|---|

| Material Gauge | A thicker tube wall directly resists bending and bowing under heavy loads. | Industrial-grade steel with a visible thickness. Avoid thin, lightweight metals. |

| Joint Construction | The connection points are the most common points of failure. | Look for clean, solid welds or robust, tight-fitting screw connections. |

| Base Design | A wide and stable base prevents the rail from tipping over, especially with uneven loads. | H-frame or A-frame bases offer superior stability compared to single-post designs. |

| Load Distribution | Even weight distribution prevents stress from concentrating on weak points. | Rails with central support legs or reinforced crossbars manage heavy loads better. |

By keeping these indicators in mind, you're not just buying a piece of metal; you're investing in a reliable tool for your business or home.

Understanding these basics is the first step. You can also get more specific details on fittings by checking out our guide on clothes rail and brackets. By examining these core features, you can confidently distinguish a reliable, long-lasting rail from one destined for the scrap heap.

Choosing Materials That Guarantee Durability

When it comes to a truly strong clothes rail, the material is everything. It’s the backbone, the very essence of its strength and longevity. Let’s be honest, not all rails are created equal, and once you look past the marketing descriptions, you’ll see some clear winners and losers.

For serious retail stock, industrial-grade steel is the undisputed champion. Its strength-to-weight ratio is phenomenal, allowing it to hold staggering amounts of clothing without a hint of bowing. Think of it like a structural beam in a building; a thick-gauge steel pipe is engineered to resist bending forces, so it stays dead straight even when loaded up with heavy winter coats or stacks of denim. This is why it’s the go-to for any demanding commercial setup.

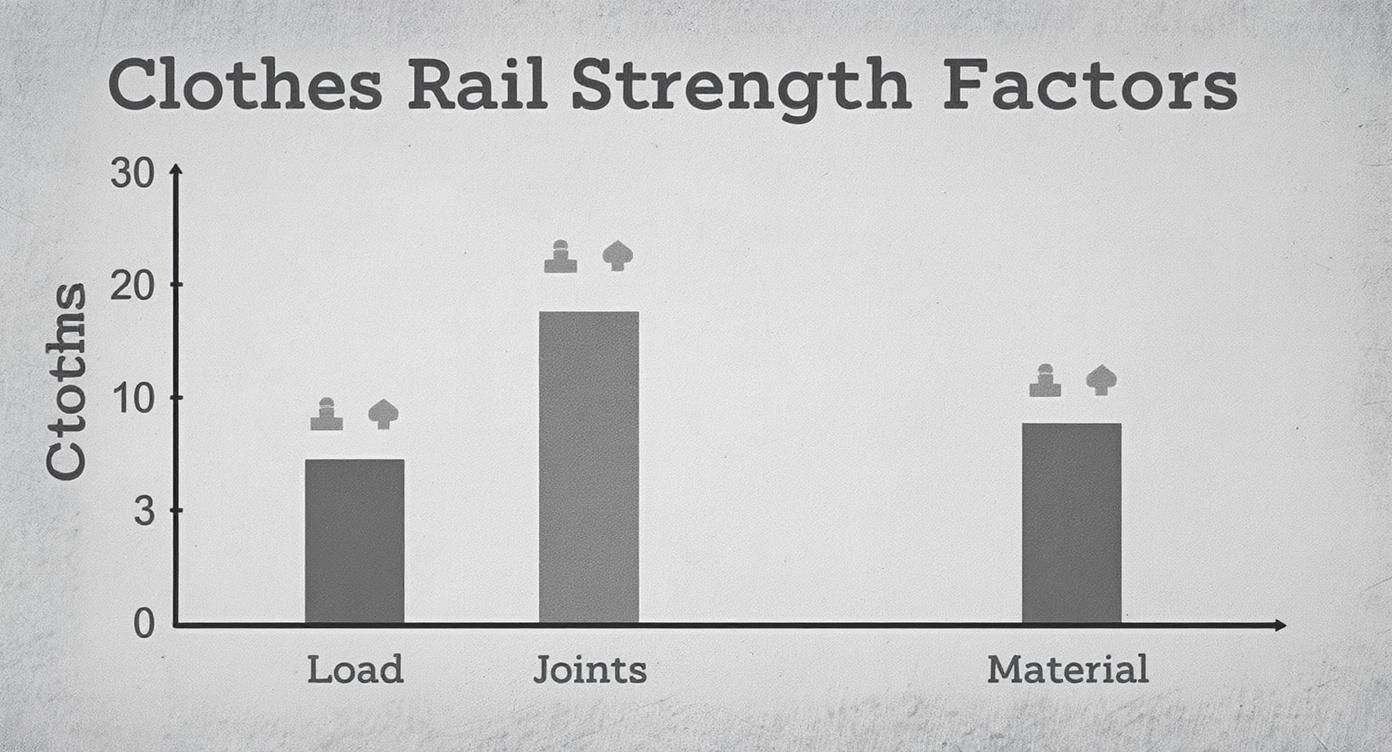

This chart really simplifies what makes a rail robust.

As you can see, the material is the foundation. It works hand-in-hand with the quality of the joints and how you manage the load to create a structure you can truly rely on.

It’s Not Just About the Metal

While the core material is absolutely vital, the finish that protects it is just as important for a long life. This outer layer is your rail’s first line of defence against the daily grind of a busy shop floor or a working studio.

- Powder Coating: This isn't just a lick of paint. A dry powder is applied using an electrostatic charge and then baked on. The result is a hard, resilient finish that’s much tougher than conventional paint, standing up brilliantly to chips, scratches, and fading. A powder-coated rail just keeps looking good.

- Chrome Plating: This gives you that classic, shiny look, but it’s much more than just a pretty face. Chrome plating provides a hard-wearing surface that offers fantastic protection against rust and corrosion—a must-have if you’re dealing with any humidity. It also makes the rail a breeze to keep clean.

These finishes aren't just for show; they’re a functional shield that will dramatically extend the life of your investment.

A Quick Guide to Common Rail Materials

To make the choice clearer, here’s a straightforward comparison of the materials you’ll most often encounter.

Material Strength Comparison for Clothes Rails

| Material | Typical Weight Capacity | Pros | Cons | Best For |

|---|---|---|---|---|

| Industrial Steel | 100 kg - 150 kg+ | Extremely strong, durable, resistant to bending | Can be heavy, higher initial cost | High-volume retail stockrooms, fashion warehouses, and commercial use. |

| Standard Steel | 60 kg - 100 kg | Good strength, versatile, often chrome-plated | Can rust if finish is compromised | Boutique displays, tailoring studios, and serious home wardrobes. |

| Aluminium | 20 kg - 40 kg | Lightweight, portable, rust-resistant | Prone to bending under heavy loads | Pop-up shops, market stalls, and temporary or light-duty home use. |

| Wood | 15 kg - 30 kg | Aesthetically pleasing, variety of styles | Lower weight capacity, can warp or weaken | Decorative displays, children's clothing, or very light home use. |

As the table shows, for any professional setting, steel is really the only way to go.

Matching the Right Material to Your Needs

Ultimately, the best material comes down to what you’ll be using it for. The logic is simple: choosing materials for their inherent properties is key, much like understanding the inherent strength and durability of gold stainless steel in jewellery making.

The strongest rails pair a high-gauge steel core with a resilient protective finish. This combination ensures the rail can handle maximum weight capacity while resisting the wear and tear of daily commercial use.

Let’s look at a few common scenarios:

- High-Volume Retail: For a busy stockroom or the shop floor, nothing beats powder-coated industrial steel. It’s built to withstand constant use and the heaviest of loads, day in and day out.

- Boutique Displays: A chrome-plated steel rail strikes the perfect balance between serious strength and a polished, high-end look. It’s ideal for front-of-house displays where presentation matters.

- Home or Studio Use: While you might be tempted by lighter options, a well-made steel rail gives you complete peace of mind. It’ll handle a growing wardrobe without any risk of collapsing. If you're weighing up different styles, it's worth exploring the variety of clothes hanging poles available to see what fits your space.

By thinking carefully about both the core material and its finish, you can choose a clothes rail that’s not just strong on day one, but remains a dependable workhorse for years to come.

Understanding Weight Capacity and Load Balance

When you see a ‘150kg capacity’ label on a clothes rail, it sounds impressive. But what does that number actually mean day-to-day? More often than not, that figure refers to a static load—the weight the rail can hold perfectly still. The real test comes the moment you try to roll that fully-loaded rail across your shop floor.

That’s where the difference between a static and a dynamic load becomes painfully clear. As soon as a rail is in motion, you introduce a whole new set of forces: vibrations, shifting weight, and new stresses on the joints and wheels. A rail that feels rock-solid when stationary can suddenly start to wobble or even fail when you move it with the same amount of stock on it.

Visualising Your Load Requirements

To pick the right rail, you first need a rough idea of how much your stock actually weighs. It’s amazing how quickly it adds up. A single heavy wool winter coat can weigh around 2.5 kg, so just 30 of them will hit 75 kg. On the flip side, 100 cotton t-shirts might only come to about 20 kg. Doing a quick back-of-the-envelope calculation of your likely maximum load will help you choose a rail that won’t just cope, but thrive.

This is more important than ever. The UK apparel market is projected to pull in roughly £68.7 billion in revenue in 2025, and that means more stock moving through shops and workrooms. Retail fixtures need to be up to the task. You can read more about UK fashion industry trends on springfair.com.

The Secret to Stability is a Uniformly Distributed Load

There's a term engineers use that is incredibly useful here: Uniformly Distributed Load (UDL). It sounds technical, but it’s a simple concept that makes a huge difference. All it means is spreading the weight out evenly across the rail, rather than dumping it all in one spot.

Piling all your heaviest items—like a dozen leather jackets or a collection of raw denim jeans—right in the middle is the fastest way to get a bowed, or even broken, top bar. This kind of focused pressure is what kills rails, even heavy-duty ones.

By balancing your stock properly, you ensure the weight is transferred down through the frame’s strongest points: the vertical supports at each end. It’s just common sense, but it’s often overlooked.

Here’s how to put it into practice:

- Heavy Items Outward: Hang your weightiest garments, like coats and chunky knitwear, towards the ends of the rail, close to the uprights.

- Lighter Items Inward: Keep lighter pieces such as shirts, blouses, and t-shirts in the centre section.

- Distribute Evenly: Try not to leave big gaps on one side while cramming clothes onto the other. An unbalanced rail is an unstable rail, and it could easily tip.

Following these simple rules will not only keep your rail safe but will also drastically extend its lifespan. For anyone with serious stockroom or retail demands, our guide on choosing a heavy duty clothing rack dives even deeper.

Freestanding vs. Wall-Mounted: What’s Best for Stability?

A strong clothes rail is only ever as stable as its setup. You can have a rail that’s supposedly capable of holding a small car, but if it wobbles, tips, or pulls out of the wall, that strength is completely useless. The real choice between a freestanding or wall-mounted system comes down to your space and what you need the rail to do.

Freestanding rails give you fantastic flexibility, but their stability is all about intelligent design. Think of it like a person standing up – a wider stance creates a much more solid base. That’s why you should always look for rails with a broad H-frame or A-frame footprint. These designs are brilliant at resisting the urge to tip over, especially when you're moving them around or the weight isn't perfectly balanced.

Freestanding Rails: It’s All About the Base

If you're using a mobile rail on the shop floor or in a busy stockroom, the castors are critical. They have to be up to the job. In my book, locking castor wheels are completely non-negotiable. They stop the rail from rolling off on its own adventures and give you a secure platform when you're loading and unloading stock.

And that central support bar you see connecting the legs? It’s doing more than just holding the frame together. It adds vital rigidity, preventing the upright poles from bowing outwards under the strain of a heavy load. It’s a small detail that makes a huge difference to the rail's long-term structural health.

Wall-Mounted Rails: Securing Your Foundation

For the ultimate in fixed, immovable stability, nothing beats a wall-mounted system. It transfers the entire load directly into the structure of your building. The catch? Its strength is entirely dictated by what you attach it to. You absolutely must know what your wall is made of before you even think about drilling a hole.

- Brick or Masonry: This is the gold standard. A solid brick or block wall provides the most secure fixing point you could ask for. Use the right masonry drill bits and some heavy-duty plugs, and you’ll have an anchor that’s practically bomb-proof.

- Plasterboard: Be warned: standard plasterboard alone is far too weak to support a heavily loaded rail. You have to find the wooden studs behind the plasterboard and fix the rail directly into them. Anything else is asking for trouble.

Choosing the right fixings isn’t just a good idea—it’s a safety essential. Trying to hang a heavy rail on plasterboard with standard screws is a guaranteed recipe for a damaged wall, a pile of clothes on the floor, and a completely collapsed rail.

The correct choice of accessories and mounting rails is critical to getting the strength you need. Never, ever rely on the flimsy generic fixings that might come in the box. Always invest in proper, heavy-duty anchors designed specifically for your wall type. We cover this in more detail in our guide to installing a wall mounted hanging rail.

Real-World Applications for Every User

It's one thing to talk about steel gauges and weight capacities, but it’s another thing entirely to see how that translates to your day-to-day. The best clothes rail isn’t just about the specs; it’s about solving a real problem, whether you’re running a busy shop, a creative studio, or just trying to get your home organised. Let’s look at what a strong rail means in practice.

For the Retail Manager

In a fast-paced retail environment, you need flexibility and serious capacity. A strong, mobile clothes rail isn't just a fixture; it's a vital tool for adapting your shop floor on the fly. Picture this: you're launching a new season's collection and need to overhaul the layout. With a set of heavy-duty rails on smooth, locking castors, you can reshape the entire customer journey in less than an hour, creating high-impact displays without calling in the shopfitters.

This kind of agility is more important than ever. With UK online apparel sales predicted to grow by 4.6% in 2025 and hit £21.01 billion, physical stores are becoming showrooms and mini distribution hubs all in one. You need back-of-house systems that can cope with a constant churn of stock. A genuinely strong clothes rail can handle hundreds of garments, moving from the stockroom to the shop floor without breaking a sweat. You can read more about the future of UK fashion ecommerce on emarketer.com.

For a retailer, a strong rail is a strategic asset. It lets you pivot your visual merchandising in minutes, handles the stock density of a massive sales event, and keeps both staff and customers safe by preventing collapses.

For Tailors and Designers

A tailor's workshop or a designer's studio is a creative space where everything needs to be organised and accessible. But the weight demands here are seriously underestimated. A single bolt of quality wool suiting can easily weigh over 15 kg. A rail might need to support several of these, plus a lineup of heavy, half-finished bespoke pieces.

For a professional like this, a flimsy rail isn't just an annoyance—it's a direct threat to expensive materials and hours of skilled work. The only real solution is a rail built from industrial-grade steel that can take the weight of dense fabrics and complex garments without a hint of bowing. A static, heavy-duty rail like the Display Guru 6ft Garment Rail provides that unwavering, workshop-ready strength.

For the Home Organisation Enthusiast

Back at home, the challenge is often finding a rail that’s both strong enough for a huge wardrobe and stylish enough to fit your decor. Think about the big seasonal wardrobe swap. A properly robust rail means you can confidently load up an entire season of heavy winter coats, chunky knitwear, and boots and store them in the spare room or loft, knowing they won't end up in a heap on the floor.

Strength is non-negotiable for common home uses like these:

- A Walk-in Wardrobe Alternative: Creating a stylish open-closet concept in a bedroom that can hold everything.

- Seasonal Storage: Safely stashing bulky out-of-season clothing in a garage or attic.

- Laundry Room Support: Having a sturdy spot to hang and air-dry heavy wet items like bath towels and jeans.

Seeing how these rails perform in the real world makes it much easier to pick the right one for your own space, whether it’s for professional or personal use.

Common Questions About Strong Clothes Rails

Even after getting to grips with the technical side of things, you probably still have a few practical questions. Choosing a clothes rail that won't let you down is a real investment, so it's only natural to want all the facts before you commit. Let's tackle some of the most common queries I hear, so you can make your final choice with complete confidence.

Getting these last few details ironed out will help you find a rail that doesn't just meet your expectations, but genuinely makes your life easier.

Does a Higher Price Always Mean a Stronger Rail?

Not always, but you definitely get what you pay for. The price tag is usually a pretty good indicator of the quality of the materials and how well the rail has been put together. If you see a rail going for a rock-bottom price, you can bet it’s made from flimsy, thin-gauge metal with weak plastic fittings or shoddy welding. It simply won't be up to the job for anything more than a handful of light shirts.

That said, you don’t automatically need to go for the most expensive option on the market. The sweet spot is finding where quality meets your actual, day-to-day needs. A mid-range industrial steel rail, for instance, often delivers the best bang for your buck, giving you serious strength without the premium cost of a bespoke designer piece. My advice? Focus on the specs—the type of metal, the thickness of the tubing, and the tested weight capacity—not just the price.

A higher price often points to better materials and craftsmanship, but true value comes from matching the rail's proven specs to what you actually need to hang. Don't overspend, but never, ever compromise on the core strength you require.

How Can I Make My Clothes Rail Last Longer?

A little bit of simple maintenance goes a long way in extending the life of your rail. You don’t need to do much, but a few good habits will prevent long-term damage and keep it performing just as it did on day one, for years to come.

Here are a few tips I always give my clients:

- Check Your Fixings Regularly: If your rail is assembled with screws, make a point to check them every few months. Give them a quick tighten if any have worked loose. This is vital for rails that get moved around a lot, as the vibrations can easily loosen connections over time.

- Keep the Castors Clean: For rails on wheels, take a moment to clear them of dust, hair, and other debris. When castors get clogged, they drag instead of roll, which puts a huge amount of unnecessary stress on the frame every time you move it.

- Wipe Down Spills Immediately: Clean up any moisture straight away to stop rust from getting a foothold. This is especially important if the protective coating on the metal has been scratched or chipped.

These small actions genuinely make a massive difference in keeping your rail structurally sound.

How Can I Estimate the Weight of My Clothes?

Figuring out your load is much easier than it sounds, and it's the single best thing you can do to make sure you buy a clothes rail strong enough for your collection. You don't need to weigh every single garment. All you need is a simple bathroom scale and a bit of common sense.

Here’s a practical way to do it:

- Grab a Representative Sample: Gather a bundle of about 10 similar items—for example, 10 heavy winter coats, 10 pairs of jeans, or 10 t-shirts.

- Weigh Yourself: First, step on the bathroom scale and note down your own weight.

- Weigh Yourself Again, Holding the Clothes: Now, pick up the bundle of clothes and get back on the scale.

- Do the Maths: The difference between the two weights is how much that bundle of clothes weighs.

- Extrapolate: If you find that 10 of your winter coats weigh 25kg, you can safely estimate that 40 coats will be around the 100kg mark.

This quick calculation gives you a realistic number to work with. It takes the guesswork out of the equation and ensures the rail you choose has the right weight capacity from the start, preventing any risk of overloading and collapse.

Ready to invest in a rail that will stand the test of time? Explore the professional-grade collection at Display Guru and find the perfect solution for your retail, studio, or home needs. Visit us at https://www.displayguru.co.uk to browse our durable and reliable options.