A Complete Guide to Heavy Duty Hanging Rails

When you hear the term 'heavy duty hanging rail', you're looking at a serious piece of storage equipment. These aren't your typical flimsy wardrobe rails; they are robust solutions, engineered from high-strength steel to take on substantial weight without even thinking about bending or breaking. They’re the structural backbone for organising everything from dense retail stock and bulky theatre costumes to heavy industrial parts.

What Makes a Hanging Rail Heavy Duty?

The label "heavy duty" isn't just a bit of marketing fluff. It points to a fundamental difference in design, materials, and overall construction.

Think of it this way: a standard garment rail is like a simple bookshelf, fine for a few paperbacks. A heavy duty rail, on the other hand, is the foundational steel I-beam of your storage system. It's built to support an entire library of hardbacks without showing any signs of strain. The whole point is to provide unwavering support for heavy loads, day in and day out, which is absolutely critical in demanding places like a bustling retail stockroom or a busy theatre's costume department.

The Key Differentiators

So, what really sets these workhorses apart from their lighter-duty cousins? It all comes down to a few key engineering decisions where strength and longevity are the top priorities.

- Superior Materials: You'll find these are almost always built from industrial-grade steel or iron. This gives them the raw tensile strength needed to resist bending under the pressure of hundreds of kilograms.

- Thicker Gauge Steel: The diameter and wall thickness of the tubing are noticeably greater than on standard rails. This extra mass is what gives it a much higher load-bearing capacity.

- Reinforced Joints: Forget simple screw-in connections. Proper heavy duty rails often feature professionally welded joints. Welding essentially fuses the connection points into a single, continuous piece of metal, getting rid of weak spots that could otherwise fail under stress.

Beyond the Wardrobe

While they're fantastic for sorting out a cluttered home wardrobe, the true value of heavy duty hanging rails shines in commercial and industrial environments. They’re designed to make workflows smoother and protect valuable inventory, whether that's automotive parts in a garage or bulky period costumes backstage. If you're curious about the different styles available, you can explore a variety of options in our guide to selecting a heavy duty wardrobe rail.

Their design isn't just about holding more stuff; it's about providing a safe, dependable, and efficient storage solution. This focus on safety and durability prevents costly stock damage, workplace accidents, and the constant hassle of replacement.

Choosing the Right Type of Hanging Rail

Finding the right heavy duty hanging rail isn’t about picking the “best” one off the shelf. It's about finding the perfect match for your space, your needs, and what you plan to hang on it. The options can seem endless, from fixed wall mounts to mobile units on wheels, but understanding the core differences is the key to making a smart choice. Each style has its own strengths, suited for very different jobs.

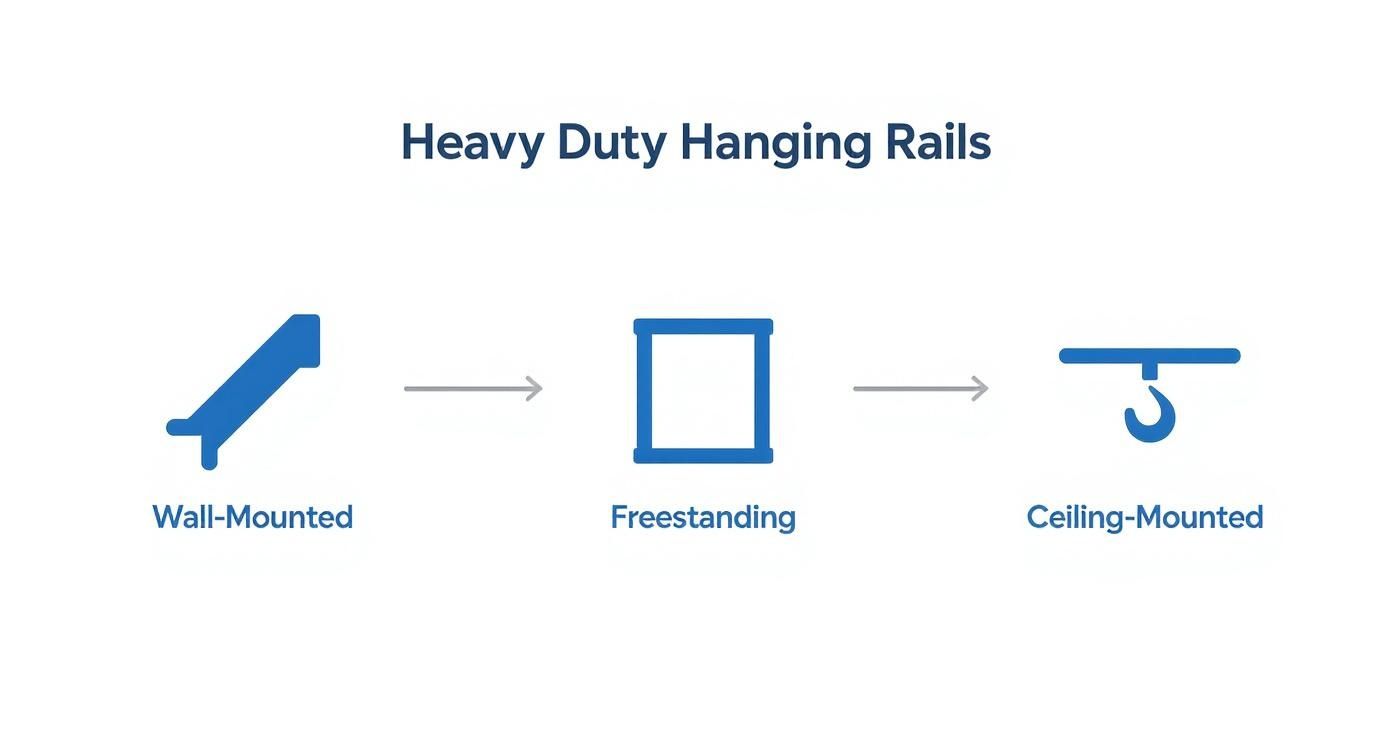

You'll mainly come across three types: wall-mounted, freestanding, and ceiling-mounted. It helps to think of them as different tools. A wall-mounted rail is like a permanently installed workshop vice – incredibly strong and fixed in place. A freestanding rail is your portable workbench, giving you flexibility and the freedom to move. And a ceiling-mounted system? That's the overhead crane, designed to lift everything up and keep your floor completely clear.

Wall-Mounted Rails: Permanent Power

For a permanent, rock-solid solution, wall-mounted heavy duty hanging rails are the undisputed champions. You see them everywhere from chic boutiques to busy stockrooms. By fixing them directly into solid brickwork or wall studs, you're transferring the entire weight into the building's structure itself, giving you incredible stability and peace of mind.

This makes them a fantastic choice for:

- Retail Displays: They create those clean, 'floating' displays that make the clothes pop, not the fixture.

- Stockrooms: Perfect for lining the perimeter walls with inventory, leaving the central floor area open for staff to move and sort goods.

- Walk-in Wardrobes: You can build a seriously robust and custom closet system without the clunky frames of traditional wardrobes.

The biggest win here is how much floor space they save. The floor is left completely clear, making cleaning a breeze and giving the room a more open, uncluttered feel. The trade-off, of course, is that they're permanent. Once they're up, they're up, so you need to be sure about the layout before you start drilling.

Comparing Heavy Duty Hanging Rail Systems

To make the choice clearer, here’s a quick side-by-side look at how these systems stack up against each other.

| Rail Type | Primary Use Case | Installation | Key Advantage |

|---|---|---|---|

| Wall-Mounted | Permanent retail displays, stockrooms, walk-in wardrobes. | Requires drilling into studs or masonry. | Maximum stability and space-saving. |

| Freestanding | Pop-up shops, market stalls, temporary storage, events. | No installation needed; just assemble. | Ultimate flexibility and mobility. |

| Ceiling-Mounted | Warehouses, workshops, industrial spaces with limited floor/wall space. | Complex; often needs professional installation into joists. | Unlocks unused vertical space. |

Each type serves a distinct purpose, so matching the rail's inherent strengths to your specific environment is the most important step.

Freestanding Rails: Versatile and Mobile

When you need flexibility above all else, freestanding rails are the answer. These are self-contained units that don’t need a single screw in the wall, making them ideal for temporary setups, rental properties, or any space where drilling just isn't an option. Their mobility means you can completely change your layout in minutes.

A high-quality freestanding rail is more than just a rack; it's a portable storage hub. You can wheel it from the stockroom to the shop floor for a flash sale, move it to a different room for a product photoshoot, or use it as an overflow wardrobe during a home renovation.

This adaptability makes them a firm favourite for pop-up shops, market traders, and event organisers. Many come fitted with heavy-duty castors for smooth movement, and some are even designed to collapse for easy transport. Just be sure to look for a model with a wide, sturdy base – the last thing you want is for it to tip over under a full load. For a closer look at the different styles available, our article on choosing a heavy duty clothing rack offers some great insights.

Ceiling-Mounted Rails: The Space Maximiser

What happens when your walls are full and your floor is cluttered? You go up. Ceiling-mounted heavy duty rails are the ultimate industrial-grade solution for tapping into unused vertical space. By suspending them directly from ceiling joists or structural beams, they can handle enormous weight while leaving your entire floor free.

You'll most often see this kind of setup in warehouses, workshops, and commercial garages. They're used for hanging everything from bulky automotive parts and industrial equipment to theatre backdrops. Be warned, though: installation is the most complex of the three. It nearly always requires a professional to assess the ceiling structure and ensure it can safely bear the weight you intend to hang. This is one job you don’t want to get wrong.

Selecting the Best Material and Finish

Choosing the right material and finish for a heavy duty hanging rail isn't just about aesthetics. It's the decision that dictates its raw strength, its lifespan, and how well it stands up to its environment. Get this right, and you've got a rail that will not only hold the weight but will also resist wear, tear, and corrosion for years to come.

At its core, a heavy duty rail is a testament to strong materials. The undisputed champion in this field is industrial-grade steel or iron. These metals are prized for their incredible tensile strength – a fancy way of saying they are exceptionally good at resisting the pulling forces created by heavy loads. This is exactly the quality you need when you're hanging hundreds of kilograms of clothing, stage costumes, or industrial equipment.

The Foundation of Strength: Materials

Think of the rail's material as its backbone. A flimsy alloy would be like having brittle bones, ready to snap under the slightest pressure. High-strength steel, on the other hand, provides the robust framework needed to prevent bowing, bending, or a complete collapse. It’s what guarantees the rail's structural integrity, day in and day out.

This infographic can help you visualise which type of rail is best suited for your space, which often points you towards the ideal material and finish.

As the decision tree shows, there's a world of difference between a permanent, wall-mounted fixture and a mobile, freestanding one. This directly impacts the level of durability you'll need for each specific job.

Finishes: The Protective Shield

If the steel is the backbone, then the finish is the rail's protective skin. It’s a vital shield against the elements, preventing damage while also adding to the overall look.

- Powder-Coated Finish: This modern technique involves electrostatically applying a dry powder which is then baked on. The result is a tough, even, and attractive finish—usually in black or white—that’s far more resilient than a simple lick of paint. It's an excellent choice for retail showrooms where appearance is just as important as performance.

- Chrome Plating: A true classic. Chrome delivers a bright, reflective, and incredibly hard surface. It offers solid corrosion resistance and is a breeze to keep clean, making it a reliable workhorse for both commercial and domestic spaces.

- Galvanised Finish: When you need the ultimate in protection, galvanising is the way to go. The steel is dipped in a bath of molten zinc, creating a barrier that is exceptionally resistant to rust. This makes it the go-to choice for damp stockrooms, industrial workshops, or garages where moisture is a constant battle.

Choosing the right finish is an investment in longevity. A powder-coated rail might look pristine in a dry shop, but a galvanised one will provide years of rust-free service in a challenging industrial setting.

Trends across the UK's commercial sector show a strong lean towards steel or iron rails with durable, stylish finishes like matte black or chrome. They hit that sweet spot between brute strength and visual appeal for retail stores and event spaces. As more businesses focus on long-term value, the demand for modular, height-adjustable heavy duty hanging rails continues to climb, making them a cornerstone of smart commercial design.

For fixed solutions where style and strength are equally important, you can learn more about picking the perfect wall-mounted clothes rail in our detailed guide. It will help you match the ideal material and finish to a secure, space-saving installation.

Calculating Your Load Capacity Needs

One of the biggest mistakes you can make when installing a heavy duty hanging rail is to just guess how much weight it needs to hold. Getting it wrong isn't just a bit of a nuisance; underestimating the load is a serious safety hazard that can lead to collapse. To pick the right rail, you've got to stop guessing and start calculating.

Think of it like putting the right tyres on a vehicle. You'd never fit standard car tyres on a huge lorry and expect it to be safe. It’s the same logic here. A rail built for a few light shirts will buckle and fail under the strain of heavy stock, leading to bent metal, damaged goods, and a real risk of injury. Getting your load capacity right is the foundation of a secure, long-lasting setup.

A Simple Way to Estimate Your Weight

The good news is you don't need any fancy equipment to get a solid idea of your total load. A basic bathroom scale and some simple multiplication will do the trick, turning a big pile of stock into a clear, usable number.

Just follow these steps:

- Grab a Sample: Pull together a small but typical group of the items you'll be hanging. If you run a clothing shop, this might be ten pairs of jeans or five heavy winter coats.

- Weigh Your Sample: Pop the items on your bathroom scale and note down the weight. For instance, ten pairs of jeans might come in at around 7kg.

- Find the Average: Divide the total weight by the number of items. In our example, 7kg divided by 10 gives you an average of 0.7kg per pair of jeans.

- Work Out the Total Load: Now, just multiply that average weight by the total number of items you plan to hang. If you want to get 100 pairs of jeans on the rail, your estimated load is 70kg (0.7kg x 100).

This simple process gives you a reliable baseline for the minimum capacity you need, taking all the dangerous guesswork out of the picture.

Why You Absolutely Need a Safety Margin

Once you've got your estimated weight, you're not quite done. It's crucial to add a safety margin. The Safe Working Load (SWL) is a limit that should never be pushed. Building in this buffer means your system can handle unexpected stresses, like a sudden influx of heavy seasonal stock or the dynamic forces of people constantly adding and removing items.

This diagram from Wikipedia neatly shows the concept of a safety factor in engineering.

The key takeaway is that your calculated weight (the 'design load') is much lower than the point where the material will actually fail (its 'ultimate strength'). The SWL sits comfortably in between, giving you that vital safety zone.

As a rule of thumb, always choose a rail with a load capacity at least 25% higher than your calculated maximum weight. If your stock adds up to 80kg, you should be looking for a rail rated for 100kg or more. This buffer accounts for things like uneven weight distribution and protects the rail's structural integrity over the long term.

Proper Installation for Maximum Safety

A heavy duty hanging rail is only as strong as its weakest link, and that link is almost always the installation. It’s no good buying a rail rated for 200kg if it's attached to a hollow wall with flimsy fixings. Getting the installation right isn't just a suggestion; it’s a non-negotiable safety requirement to make sure your rail performs as promised without any risk of catastrophic failure.

The work starts long before you even pick up a drill. Your first and most crucial job is to figure out what kind of wall you’re dealing with. Is it solid masonry like brick or concrete? Or is it a hollow plasterboard wall built on a timber stud frame? Each one needs a totally different approach and specialist hardware to get a solid, reliable fix.

Matching Fixings to Your Wall Type

Choosing the right hardware is everything. Using the wrong type of fixing is a common—and frankly, dangerous—mistake that can lead to the entire rail pulling away from the wall once it’s loaded up.

Here’s a quick rundown of the essentials:

- For Solid Walls (Brick/Concrete): You’ll want heavy-duty sleeve anchors or lag shields with lag screws. These expand inside the wall, creating an incredibly powerful mechanical grip that can handle serious weight.

- For Plasterboard Walls: You must find the vertical timber studs behind the plasterboard. Use a stud finder for this, then drive long screws directly into the studs to anchor the rail to the building's skeleton.

- For Hollow Sections (No Studs): If hitting a stud just isn’t possible, your only safe bet is to use specialist hollow-wall anchors, like heavy-duty toggle bolts. These work by spreading the load across a much wider area of the plasterboard, stopping it from just pulling through.

When thinking about safety procedures for this kind of work, it's always wise to apply the principles of the hierarchy of controls to remove risks at their source.

Common Installation Mistakes to Avoid

Even if you have the right fixings, a few simple slip-ups can compromise the whole setup. Knowing what these common pitfalls are can be the difference between a secure rail and a potential disaster. A properly installed rail protects both people and property.

A secure rail is an invisible success; a failed one is an expensive and dangerous lesson in gravity. Always double-check your work and, if in any doubt, consult a professional installer for peace of mind.

To make sure your rail is safe and built to last, steer clear of these mistakes:

- Ignoring Wall Studs: This is the number one cause of failure. Not finding and fixing into studs on a plasterboard wall is asking for trouble.

- Using Undersized Fixings: Never, ever use standard plastic wall plugs for a heavy duty rail. They simply can’t handle the shear forces and will inevitably pull out.

- Not Levelling the Rail: A rail that isn't level distributes weight unevenly. This puts far too much strain on one set of fixings, weakening the entire installation over time.

For a deeper dive into mounting techniques, our guide on selecting a hanging rail wall mounted system offers more specific advice and product ideas.

Heavy Duty Rails in UK Industrial Sectors

When you think of a hanging rail, you probably picture a clothes shop stockroom or maybe even your own wardrobe. But step outside the high street, and you’ll find that heavy duty hanging rails are a critical piece of the UK’s industrial puzzle. In sectors where strength and reliability are non-negotiable, these systems are the unsung heroes keeping things moving.

Take logistics and manufacturing. Here, these rails aren't just for clothes; they’re used to hang everything from bulky car exhaust pipes to complex wiring looms. This keeps essential components organised, easy to grab, and crucially, safe from damage on a busy factory floor. It’s a smart way to clear valuable floor space and eliminate tripping hazards. For anyone dealing with particularly long or awkward items, looking into specialised solutions like cantilever warehouse racking systems can offer even more tailored storage options.

Backbone of National Infrastructure

Perhaps their most vital role is one you might not expect: within the UK's railway network. Specially engineered heavy duty rails are used as essential fixtures and fittings, securing the tracks themselves under the colossal weight and stress of daily train travel. And the demand for these tough-as-nails components is on the rise.

It's a growing market. In 2024, the UK's railway track fixture sector expanded by 12%, hitting a value of $158 million. This jump reflects a serious investment in our national infrastructure and puts a clear premium on the quality and durability needed to keep our transport networks running safely.

This reliance on high-strength fixtures really brings home their economic and engineering significance. The health of this market is a direct reflection of the need for specialised heavy duty rails, proving just how fundamental they are to the country.

From securing freight to supporting the very railway lines we depend on, these components are so much more than simple storage. They are integral to the safety and efficiency of the industries that form the UK's economic backbone. If you're looking into options for your own business, our complete guide to heavy duty rails is a great place to start.

Got Questions? We've Got Answers

When you're dealing with heavy-duty hanging rails, a few questions always seem to pop up. Getting them answered properly is the difference between a secure, long-lasting installation and a potential disaster. We've pulled together the most common queries we hear to give you some clear, practical advice.

Think of this as your quick-start guide to sorting out those nagging little details, from what your walls can handle to keeping your rail in top shape.

Can I Mount a Heavy Duty Rail on a Plasterboard Wall?

Absolutely, but you have to do it right. Just using the standard screws that come in the box is asking for trouble – they’ll pull straight out of the plasterboard once you load the rail up.

The key is to bypass the plasterboard and anchor directly into the solid structure behind it. You'll need a stud finder to locate the vertical timber studs within the wall. Driving long, heavy-gauge screws through the plasterboard and deep into these studs is the gold standard, as it transfers the entire weight load to the frame of the building.

If you can't line up with a stud, your next best bet is to use specialist hollow wall anchors, like snap toggles or molly bolts. These clever fixings expand behind the board, spreading the load over a much wider surface area to prevent it from tearing through.

How Do I Figure Out How Much My Clothes Actually Weigh?

It's easier than you think, and you don't need to guess. A simple household scale will give you a surprisingly accurate idea of the load you're planning to hang.

As a rough rule of thumb, a linear foot of hanging space filled with mixed clothing comes in at around 7-9kg (15-20 lbs). For a more precise figure, grab ten typical items from your wardrobe, weigh them together, and calculate the average. Multiply that number by how many garments you want to hang, and you'll have a solid estimate to work with.

What’s the Best Way to Clean and Maintain My Hanging Rail?

A little bit of care goes a long way and keeps your rail looking good and working perfectly for years. The good news is, it’s incredibly simple.

For most finishes, like powder-coated steel or polished chrome, a quick wipe with a soft, damp cloth is all it takes to remove dust and smudges. The most important thing is to avoid harsh, abrasive cleaners or scourers, as they can easily scratch the surface and damage the protective coating.

It's also a good habit, especially in a busy retail or stockroom setting, to give the wall fixings a quick check every now and then. Just make sure everything is still nice and tight, as constant use and vibrations can sometimes cause things to loosen over time.

Ready to find the perfect rail for your space? Explore our complete range of robust and reliable garment rails, designed for every application, at Display Guru. Discover your ideal storage solution today at https://www.displayguru.co.uk.