Choosing the Right Heavy Duty Hangers for Your Business

A proper heavy duty hanger isn't just a beefed-up version of what you have at home. It’s a specialist tool, engineered to hold serious weight without giving in—no bending, no snapping, and absolutely no damage to the garment it's holding. We've all seen a standard plastic hanger buckle under the strain of a winter coat; these are built differently to protect the shape and structure of your most valuable items.

What Defines a True Heavy Duty Hanger

Ever gone to your wardrobe and found a favourite coat in a heap on the floor, its hanger broken clean at the neck? That’s the classic sign you need something more robust. The difference between a standard hanger and a heavy-duty one isn't just a bit of extra plastic; it’s a completely different approach designed for demanding loads.

Think of it like the foundation for a house. You wouldn't build a solid brick home on a flimsy base, and the same logic applies here. A weak hanger just can't provide the support needed to protect a valuable, heavy garment. This idea of building for strength isn't unique to hangers, of course. You can see the underlying principles of heavy-duty construction, as seen in sewing machines designed for thick materials, which shows how durability is engineered into all sorts of professional tools.

The Core Principles of Strength and Support

At its heart, a professional-grade hanger is a combination of three key things: the right materials, intelligent structural design, and high-quality construction. It’s not just about hanging something up; it’s about actively preserving it. The entire point is to spread the garment's weight evenly across the hanger, eliminating stress points and making sure the item keeps its intended shape for years to come.

This is absolutely crucial in a professional environment, where every garment is an investment and a key part of your brand's image.

A well-chosen heavy duty hanger does more than just hold clothing; it protects assets, preserves craftsmanship, and upholds a standard of quality. It is the silent partner in maintaining the value of your inventory.

Why It Matters for Your Business

If you're a retailer, a tailor, or running a costume department, the right hanger is simply non-negotiable. It's what ensures a bespoke suit jacket keeps its sharp shoulder line, a heavy leather coat doesn’t get stretched or marked, and an intricate costume is supported safely. This commitment to quality should run through your entire display setup. For more on this, check out our guide on choosing a heavy duty clothes rail that can bear the weight of a full collection.

At the end of the day, investing in proper heavy-duty hangers gives you real, practical benefits:

- Garment Protection: You can say goodbye to stretching, sagging, and other damage caused by poor support.

- Preservation of Shape: It keeps the intended drape and form of tailored or heavy pieces exactly as the designer intended.

- Professional Presentation: Your stock will look its absolute best, whether in a showroom or on the shop floor.

- Long-Term Reliability: It cuts down on the costs and hassle of replacing broken hangers and, even worse, damaged goods.

Getting to Grips with Hanger Materials and Build Quality

The material of a heavy duty hanger is its very essence. It's what determines its strength, how long it will last, and even the impression it gives. Think of it less like a simple hook and more like a specialised tool – choosing the right one is the first real step in protecting your garments properly.

In the professional world, it really boils down to three main players: solid wood, stainless steel, and industrial-grade plastics. Each has its own distinct personality and purpose, making them a better fit for some jobs than others. Understanding what sets them apart is crucial to making a smart purchase.

Solid Wood: The Gold Standard for Presentation

When you want to make a statement, you reach for wood. Solid wood hangers, especially those crafted from hardwoods like beech or ash, are the definitive choice for high-end retail displays and sophisticated wardrobes. Their chunky, contoured shape provides brilliant support for the shoulders of suits and jackets, stopping that awful creasing and puckering you get from flimsy alternatives.

But it’s not just about function. A row of polished wood hangers adds a touch of class and quality to a shop floor. It signals value to a customer before they've even laid a hand on the garment. While they might not be the absolute strongest for truly extreme weights, their combination of solid support and visual elegance is perfect for tailored outerwear.

Stainless Steel: The Undisputed Workhorse

When sheer, brute strength is what you need, nothing beats stainless steel. These are the heavy duty hangers built for the toughest jobs. You'll find them in busy stockrooms, professional costume departments, and industrial settings where things like heavy leather jackets, military uniforms, or beaded wedding gowns need to be stored without a second thought.

Steel hangers are also resistant to rust and corrosion, which is a massive plus in unpredictable storage conditions. Their slim profile is another key advantage; you can fit far more garments onto a rail compared to their bulkier wooden counterparts. It’s this blend of incredible strength and space-saving design that makes them the backbone of any serious back-of-house operation. The demand for this kind of durability is growing, with the Europe hangers market projected to expand at a CAGR of 4.4% between 2023 and 2030, led by metal and steel hangers valued for their longevity. You can read more about the European hanger market and its growth.

Industrial-Grade Plastics: The Versatile All-Rounder

Forget the cheap, brittle plastic hangers that snap if you look at them the wrong way. Modern industrial-grade plastics are a different breed entirely. Reinforced with advanced polymers, they offer a fantastic balance of strength, flexibility, and value for money.

They're lightweight yet tough and can be moulded into all sorts of specialised shapes, often with built-in clips or non-slip grips. This makes them a brilliant all-round option for a huge variety of clothing, from silky blouses to heavy work trousers. For any business that needs a large volume of dependable hangers without the premium price tag of wood, reinforced plastic is a very smart move.

To help you decide, here’s a quick comparison of the main material types.

Heavy Duty Hanger Material Comparison

| Material | Best For | Durability | Aesthetic | Average Load Capacity |

|---|---|---|---|---|

| Solid Wood | Premium retail, suits, jackets, showrooms | High | Excellent, luxurious | 5-10 kg |

| Stainless Steel | Stockrooms, industrial use, heavy costumes, leather | Exceptional | Utilitarian, professional | 15-25 kg+ |

| Industrial Plastic | General retail, high-volume stock, trousers, varied garments | Very Good | Functional, modern | 4-8 kg |

Ultimately, the right material choice depends entirely on the job you need the hanger to do.

The real measure of a heavy duty hanger isn't just the material itself but the quality of its construction. A poorly assembled hanger, regardless of material, will fail. Look for single-piece builds, reinforced neck joints, and securely integrated hooks as signs of superior manufacturing.

A well-made hanger is an investment that will pay off for years. But remember, it's only one part of the system. Pairing great hangers with equally robust supports is just as important. To make sure your whole setup is built to last, from hook to floor, take a look at our guide on choosing the best heavy duty rails.

Understanding Hanger Weight and Load Capacity

While the material and build quality give a hanger its backbone, the single most important number on its spec sheet is the load capacity. This isn’t just a helpful guideline; it’s a critical performance metric that tells you precisely how much weight the hanger can reliably support before it starts to bend, warp, or fail entirely. It’s a detail that’s all too easy to overlook, often with costly consequences.

Ignoring load ratings is a bit like trying to tow a heavy caravan with a standard family car—you might get a little way down the road, but sooner or later, something is going to give. The constant strain on an overloaded hanger causes gradual damage, not just to the hanger itself but also to the garment it's holding. This can show up as sagging shoulders on a prized jacket or, in the worst-case scenario, a sudden snap that sends expensive stock tumbling to the floor.

Grounding the Numbers in Reality

To choose the right hanger, you need a realistic sense of what your garments actually weigh. Abstract numbers on a product page don't mean much without some real-world context.

Here are a few typical examples to get you thinking:

- A heavy wool winter coat can easily weigh 3 kg.

- A classic leather motorcycle jacket often tips the scales at over 4 kg.

- An embellished theatrical gown or a ceremonial robe can weigh significantly more, depending on the fabric and detailing.

A quick assessment of the heaviest items in your collection will give you a baseline to work from. As a rule of thumb, it’s always smart to choose heavy duty hangers with a load capacity at least 50% greater than your heaviest garment. This creates a sensible safety margin, accounting for long-term stress and giving you complete peace of mind.

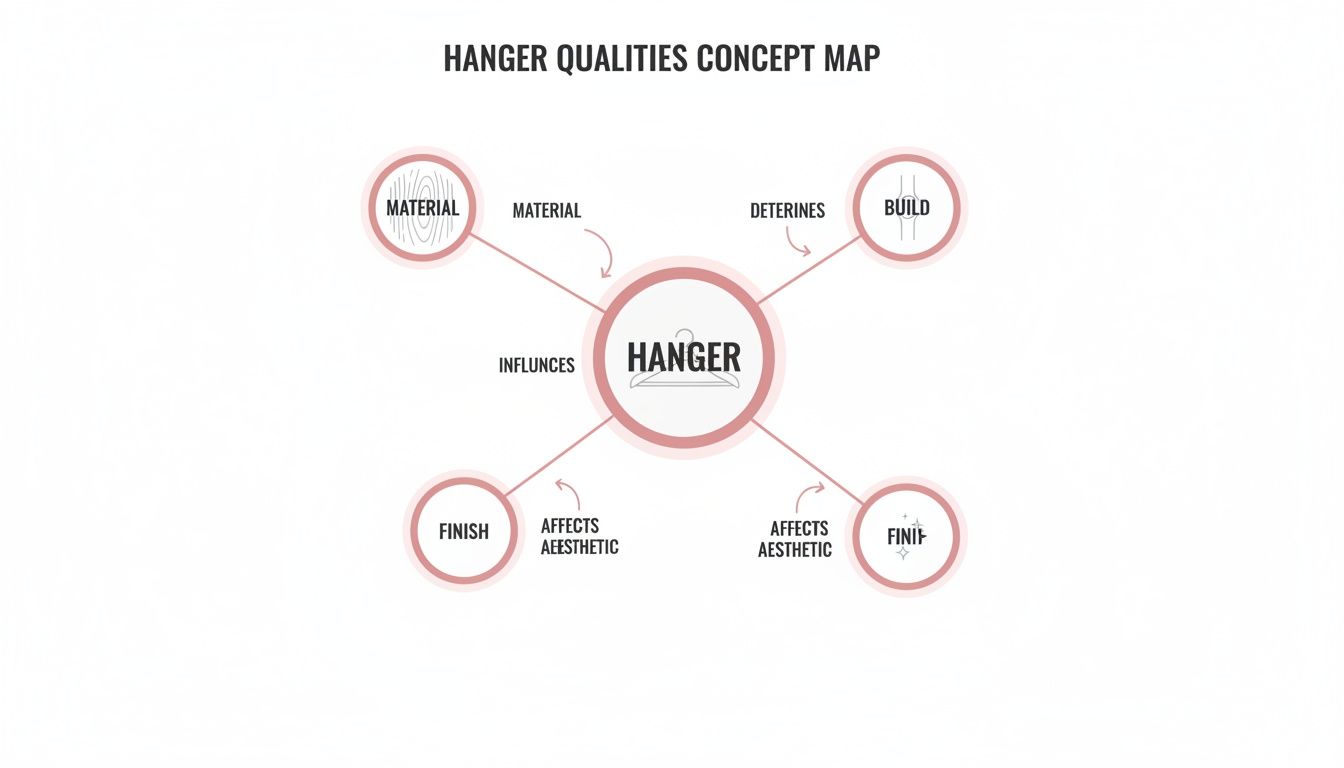

This concept map breaks down the core qualities that contribute to a hanger's overall strength and reliability.

As you can see, a hanger's performance isn't down to just one thing. It's the result of its material, build, and finish all working together to support the load.

As you can see, a hanger's performance isn't down to just one thing. It's the result of its material, build, and finish all working together to support the load.

Matching Capacity to Your Display System

Of course, a hanger’s strength is only one part of the puzzle. Your entire storage system, from the individual hanger right up to the rail, needs to handle the cumulative weight of your stock. There’s no point using hangers rated for 10 kg each if the rail they’re all hanging on can only support a total of 50 kg.

The total weight on your rail is the weight of all your garments combined. Always ensure your support structure's capacity far exceeds the total load to prevent catastrophic failure, which could damage your entire collection.

This idea of a strong, unified system is absolutely vital for both safety and efficiency. To learn more about selecting the right foundation for your display, check out our detailed guide on how to choose a strong clothes rail that won't let you down. Investing in the right hangers is the first step, but ensuring they’re part of a robust system protects your garments, maximises their lifespan, and preserves their value.

Matching Hanger Shape to Garment Integrity

While a hanger's strength is crucial for holding weight, its shape is what truly protects a garment's structure. Think of it like this: using the wrong hanger, even a strong one, is like parking a car with one wheel halfway up the kerb. It puts unnatural stress on the frame, and over time, that stress causes damage. In a professional environment, one size never fits all.

The best hanger designs are all about ergonomics; they’re engineered to mimic the human form, providing support exactly where it's needed most. This turns storage from a passive activity into an active form of garment preservation. For your valuable stock, getting the shape of a heavy duty hanger right is every bit as important as its material.

Supporting Tailored Shoulders

When it comes to tailored garments—suit jackets, blazers, coats—the shoulder line is everything. A standard, flimsy hanger forces the garment’s entire weight onto a tiny pressure point. Before you know it, you've got unsightly puckers and stretched fabric.

This is exactly why contoured, wide-shoulder hangers are non-negotiable for formalwear. Their broad, curved shape perfectly mirrors the natural slope of a person's shoulders, distributing the weight evenly across a much wider surface. This simple change prevents the fabric from drooping or developing those tell-tale bumps, keeping the crisp, structured line the tailor worked so hard to create. A well-supported shoulder is vital for presentation, a principle that’s just as relevant when learning how to dress a mannequin for maximum visual appeal.

The goal is to make the garment 'think' it's still on a person. The right hanger shape provides structural memory, ensuring the item retains its intended drape and form, ready for the showroom or the fitting room.

The industry certainly understands the importance of proper garment care. In the UK, the clothes hanger market holds an impressive 11.80% share of the entire European market. For professionals, investing in properly shaped heavy-duty hangers is a smart move, as it can reduce wear and tear by up to 30% compared to standard hangers.

Preventing Creases and Marks

Beyond the shoulders, other design elements are just as critical for maintaining garment integrity. Trousers, particularly those made from fine wool or delicate fabrics, need specific support to avoid the sharp, permanent crease you get from folding them over a simple bar.

Specialised heavy duty hangers solve this problem with purpose-built features:

- Felted or Rubberised Bars: These create a non-slip, cushioned surface that grips the fabric gently. This simple addition prevents that hard, horizontal crease that a smooth plastic or wooden bar inevitably leaves behind.

- Sturdy Clips: For skirts and trousers that hang best from the waistband, you need strong clips with protective rubber tips. They provide a secure hold without crushing the fabric or leaving permanent indentations.

By carefully matching the hanger’s shape and features to the specific garment, you’re actively protecting your inventory from damage. It’s the key to ensuring every single piece remains in pristine, ready-to-sell condition.

Selecting Hangers for Professional Environments

It’s one thing to know the theory, but putting it into practice is where things get interesting. The perfect heavy duty hanger isn’t a one-size-fits-all solution. Its design has to be perfectly matched to the unique demands of its environment.

A bustling retail floor, a meticulous tailor's workshop, and a chaotic backstage costume department all have completely different needs. Choosing the right hanger isn't just about hanging clothes; it's a practical business decision that affects your efficiency, your presentation, and the lifespan of your valuable stock.

By really getting to grips with the challenges of your profession, you can choose wisely and genuinely enhance your operations. Let's break down what that looks like across a few key industries.

For Retail Showrooms and Boutiques

In retail, a hanger has to work twice as hard. It's there to support the garment, of course, but it's also a crucial part of your shop’s overall aesthetic. First impressions count, and a cohesive, premium display instantly elevates how customers perceive your merchandise.

This is why solid wood hangers are so often the go-to choice. They have a luxurious look and feel that creates a clean, organised, and aspirational atmosphere. On the other hand, slim-profile metal hangers can be just as effective in modern or industrial-themed spaces, and they have the added benefit of letting you fit more garments onto a single rail. If you’re keen to learn more about creating stunning displays, our visual merchandising guidelines are packed with tips on turning your showroom into a truly compelling space: https://www.displayguru.co.uk/blogs/news/visual-merchandising-guidelines.

A few key things to think about for retail:

- Aesthetic Cohesion: Do the hangers genuinely reflect your brand’s style?

- Customer Experience: Can shoppers easily take items off the rail without a struggle?

- Space Efficiency: Does the hanger’s profile help you make the most of your display space?

To complete the look, many professional brands integrate custom hang tags. This final detail is essential for branding and communicating product information, creating a polished and professional presentation.

For Tailors, Designers, and Bespoke Ateliers

For a tailor or designer, a hanger's most important job is preservation. From the moment a garment is finished, its precise cut, drape, and form must be perfectly maintained. The hanger becomes the silent guardian of true craftsmanship, protecting countless hours of meticulous work.

This is an environment that calls for hangers with superior ergonomic shapes. You’ll need wide, contoured shoulder hangers for jackets and coats to prevent any pulling or distortion. For trousers, hangers with soft-felted or rubberised bars are non-negotiable, as they stop sharp creases from forming in delicate fabrics like wool or linen. Here, it’s all about pure function and the gentle, accurate support of the garment’s structure.

A bespoke garment is a work of art, defined by its lines and silhouette. The right hanger acts as a frame, preserving the integrity of that art from the final stitch to the moment it is worn.

For Costume and Theatre Departments

The storage challenges in costume departments are in a league of their own. Garments here are often incredibly heavy, laden with elaborate beadwork, multiple layers, or even built-in structural components. They can also be unusually shaped, making standard hangers completely useless. The number one priority is simply uncompromising strength and versatility.

This is where industrial-strength stainless steel heavy duty hangers really come into their own. Their exceptional load capacity can handle the immense weight of ceremonial robes, complex period costumes, and full-body mascot outfits without any risk of bending or breaking. You'll often find that specialised hangers with extra-long hooks or adjustable clips are needed to accommodate the most unconventional items.

Organisation is another huge factor. In the fast-paced world of a production, costumes need to be stored securely but remain easily accessible. Think of a medical drama, for instance; they might use hangers strong enough to hold heavy lead aprons, which must be hung properly to prevent cracks forming in their protective core. This same principle of using robust, purpose-built hangers applies directly to the unique demands of the theatre.

Your Heavy-Duty Hanger Questions Answered

When you're investing in professional-grade kit, you want to be sure you're making the right choice. It’s no different for something as fundamental as heavy-duty hangers. A few questions tend to pop up time and again, so let's clear up any doubts and get you pointed in the right direction.

Think of this as the practical knowledge you need to choose wisely and protect your most valuable garments for years to come.

How Do I Figure Out the Right Weight Capacity?

The best way to start is surprisingly simple: weigh your heaviest garments. A big winter coat or a proper leather jacket, for example, usually lands somewhere between 2-5 kg. Once you know that, here's the professional rule of thumb: always pick a hanger with a load capacity at least 50% higher than your heaviest item.

That extra buffer is your safety net. It means the hanger won't strain, bend, or break under a constant load, providing solid, long-term support for your best stock and preventing any slow, creeping damage to the garment itself.

Are Wood Heavy-Duty Hangers Better Than Metal Ones?

Honestly, they're just different tools for different jobs. Solid wood hangers give you that premium look and fantastic shape support, which is exactly what you want for suits and jackets in a high-end retail showroom. They just ooze quality.

Metal hangers, on the other hand, are all about raw strength and a slimmer profile. This makes them the workhorse for maximising space in the stockroom or for handling seriously heavy items like wedding dresses, elaborate costumes, or even multiple garments on one hanger.

Choosing between wood and metal isn't about which is "better"—it's about which is the right tool for the job. One is for presentation, the other is for pure, utilitarian strength.

Can I Just Use One Type of Hanger for Everything?

For professional results? Absolutely not. Trying to get by with a single, one-size-fits-all hanger is one of the most common and costly mistakes we see. A wide, contoured suit hanger will stretch out a delicate knit in no time, while a simple bar hanger does nothing for the shoulders of a tailored jacket.

The smart move is to build a small, curated collection. Use those shaped, contoured hangers for outerwear, grab the clipped ones for skirts and trousers, and keep slim-profile hangers for shirts. This approach ensures every single garment gets the support it needs, which stops it from getting damaged or losing its shape.

How Do I Look After My Hangers to Make Them Last?

A little bit of care goes a long way. For wooden hangers, a regular dusting with a dry cloth is all you need, and it’s best to keep them out of really damp environments. Metal hangers just need a quick wipe-down now and then to stay in top shape.

It's also a good idea to periodically check that any protective bits—like the rubber tips on clips or the felt on trouser bars—are still in place to prevent snags. But the most important thing? Never, ever go over the recommended weight capacity. Overloading is the number one reason hangers fail, no matter what they're made of.

At Display Guru, we specialise in the display solutions that professionals trust. Have a look at our complete collection of garment rails and display forms to build a system that protects and presents your inventory perfectly.